What's with LED strips? Why can't they all just be the same voltage? You may well ask...

There are several pros and cons to both 12-volt and 24-volt strips that make them more suited to different projects. If you'll be undertaking an LED lighting project shortly, I highly recommend you read this article to learn which of these options is the right choice!

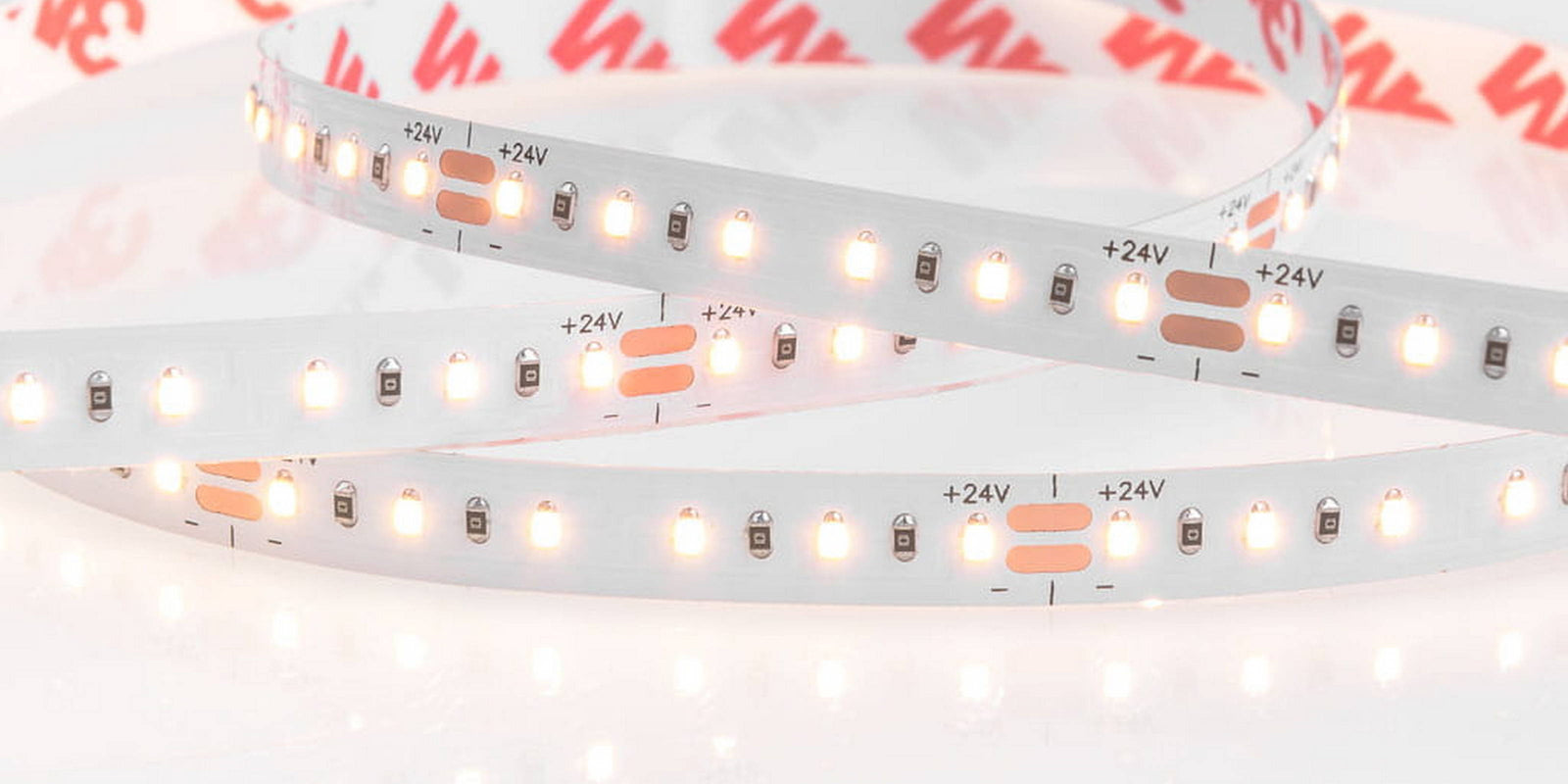

The great debate: What should it be, 12V LED or 24V LED strip?

Depending on your project, you might want to use a 12V or 24V LED system. Here is our guide to show you which one is best for your next low-voltage lighting design.

Buy 12-volt strips here.

Buy 24-volt strips here.

The Advantages of 24-volt LED strips

We'll cut to the point here and now. In most cases, a 24V LED strip is the ideal solution. Why? For the reasons below...

Requires half the current

Because 24V strips are double the voltage, they only require half the current of their 12V cousins. This can make a big difference in the amount of control gear required. The easiest way to understand this is by simply using the illustration below.

A 24V system with a max output of 6 amps results in 144 watts of power.

24 x 6 = 144

A 12V system with a max output of 6 amps results in 72 watts of power.

12 x 6 = 72

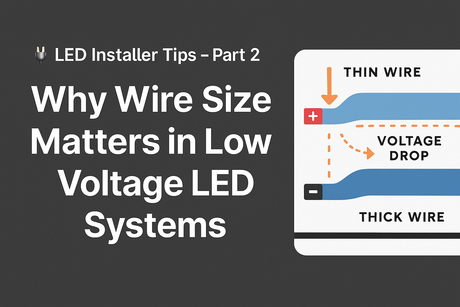

Better Energy Efficiency

12V LED strips can be less energy efficient. This is also due to the higher current required. Current is limited by the thickness of the wires the electricity is running through. If the wires are not thick enough, a significant fraction of the current will be turned into heat energy. This is not only a waste: in some cases, it can even be a fire hazard!

Requires Thinner Wiring

We've just explained why 24V strips can be powered with thinner wire, and how that increases energy efficiency, but there are more advantages to thinner wiring. Thinner wires are easier to work with and are less expensive. While this may not be a deciding factor in smaller projects, when you're working on a large project, with long runs of wire, this can make a significant impact!

Best When Higher Brightness Is Required

When you need some serious light output 24V is once more a clear winner. This again is due to the lower current required.

The voltage itself does not make any difference to light output, but rather the number of LEDs and their quality. A 24V LED strip can have double as many LEDs but draw the same current as a 12V strip. This makes 24V more suitable because if you put more LEDs on a 12V strip, the thin wires on the strip would be overloaded.

Better For Longer Runs of Strip

When it comes to 12 volt vs 24 volt LED strips, one of the main differences between the two is the fact that the 24V strips can be run for longer distances than the 12V strips can due to voltage drop.

Voltage drop is the gradual decrease in voltage along a circuit due to the resistance of the conductors. Because 24V LED tape requires a lower current for an equivalent power output, its voltage drop is proportionately less. Therefore, if your project requires a very long run of LEDs from a single power source, we would recommend that you use 24V strips.

Pro tip: Wiring an LED strip from both ends doubles the length you can run before voltage drop becomes an issue.

The Advantages of 12-volt LED strips

So are 12V strips made redundant by their clear disadvantage to 24V? By no means! There are advantages specific to 12V strips that can make them more suitable for your project.

Has Short Cutting Increments

The length of the cutting increment on a 12V LED strip will generally be half that of a 24V strip. You'll be able to snip your strip closer to the exact length you need! This can make a significant difference when installing LEDs in small spaces, like inside cabinets.

Matches Common Vehicle Voltage

Cars, trucks, and boats run on 12V of power 99% of the time. This means that 12V LED strips can be integrated with existing electrical components, without having to convert the voltage!

Lower Initial Cost

12V strips are generally a little cheaper. While a lower upfront cost is great, don't forget that 24V strips are slightly more efficient, require less control gear, and can use thinner (cheaper) wiring.

Which LED Strip Is Right For My Project - 12V or 24V?

The difference between 12V and 24V LED strip types available on the market is significant, but one of the most important decisions you'll need to make is whether to go with a 12V or 24V strip for your low-voltage lighting project. Here are some common LED projects, and the best-suited voltage for them!

Common 24V LED Lighting Applications

- When a high light output is required.

- When you're running a long length of LED strip from a single power source.

- When you have existing 24V lighting that your strip can be integrated with.

Common 12V LED Lighting Applications

- In vehicles such as cars and trucks.

- On boats and docks.

- When a more specific length is required.

- When you have existing 12V lighting that your strip can be integrated with.

Debunking 12-volt vs 24-volt LED Strip Myths

A few common misconceptions people have about LED strip voltage:

The higher the voltage the brighter the light

This is not factually correct, but voltage does have an indirect bearing on light output. The higher the voltage, the less current is required. Due to this more individual LEDs can be built into the strip — and the more LEDs you have the brighter the strip.

The higher the voltage the higher the energy consumption

This is not true. A higher voltage simply balances out by using fewer amps. A 12V strip requires more current (amps), and when the wires are not thick enough to accommodate this higher current the electricity is wasted as heat energy!

12V and 24V LED strips have different lifespans

When properly installed, 12V and 24V LED strips have the same lifespan, barring external factors of course. If you install your strip with wiring incapable of handling the higher current required for a 12V strip there will be excess heat, which in turn can damage LED strip components.

Key Takeaways - The Pros and Cons of 12V and 24V LED Strips

The long and short of it? When you can use 24V, the advantages make it a clear winner. If you're still unsure, don't hesitate to reach out to us and we'll answer all of your LED questions! If you've decided, check out our commercial-grade LED strips here.

12V

- Can be cut to a more accurate length.

- The same voltage as boats, cars, and trucks.

- A slightly lower upfront cost.

24V

- Can power longer runs without significant voltage drop.

- Runs more efficiently.

- Requires thinner wiring and less control gear.

- Best for projects that require a bright light.

Buy 12-volt strips here.

Buy 24-volt strips here.

Frequently asked questions

Q: Does voltage determine the light output of the LED strip?

A: Many people believe that the voltage affects the lighting fixture's brightness but the reality is that there is no difference in brightness between a 12V and 24V LED strip light; the voltage does not determine the light output.

Q: Are 12V And 24V strip lights compatible?

A: No, 12V strips can get excessively hot within a few seconds of being connected to a 24V power supply unit. Simply put, connecting 24V to the 12V LED strip copper pads could cause the LEDs to burn out due to over-voltage.

If you try to do the reverse and connect a 24V LED strip to a 12V system, it will either not turn on at all or have a dimmed appearance. This applies to any 24V lights on a 12V system, not just to LED strips. We always advise verifying that the power supply's requirements for the voltage match the voltage of the LED strip.

Q: 12V vs. 24V LED tape light — Which is better?

A: You should now have a good understanding of the benefits and drawbacks of 12V vs. 24V LED strip lights. If the cut length isn't a concern, 24V strips are ideal because you can spread them further. If your project requires shorter cutting increments due to spatial issues, a 12V strip should be your go-to option.

Using a 24V LED strip instead of a 12V strip can dramatically reduce the amount of wiring required, saving you money in the process. Increasing the voltage causes a reduction in the current flowing through the system, meaning you can use thinner wires that are less expensive. And you require fewer supply connections for the same size installation.

Q: Are all LED lights low voltage?

A: LED lights come in two versions: a line-voltage version that can be directly operated on a 120V mains supply and a low-voltage version that can be operated on a 12V or 24V power supply. Line voltage LED lights come with their own integrated power supply unit, so they can be connected directly to an outlet without any extra power supply needed. 12V and 24V lighting systems need a transformer or LED 'driver' for operation. But this is not necessarily a disadvantage — they have high efficiency meaning a longer lifespan, and you won't be dealing with hazardous voltages.

Q: Are all LED light strips compatible?

A: LED strip lights are a great way to light up a space, but not all LED strip lights are compatible with one another. Even though you can easily connect two LED strip lights together, it is important to ensure that the voltage of the strips is the same and that the polarity is matched.

Q: Can you connect LED lights together?

A: Yes, you can connect LED lights together. They can be linked in series or parallel depending on your specific setup and requirements. It's important to ensure that the voltage and polarity of the LED lights match to create a seamless and functional lighting system.

Q: Are all LED lights 12 volts?

A: The answer is no — and in fact most of our LED strips are 24V. We carry a few models in 12V, and then there is our Visive range which is 48V LED light strip for very long installations. Each has its own pros and cons.