Fire-Resistant Aluminum Composite Material Panel ~ ALPOLIC/fr Series

Regular price $0.00 USDUnit priceUnavailableHeavy Duty Aluminum Composite Material Panel ~ ALPOLIC/HD Series

Regular price $0.00 USDUnit priceUnavailableLightweight Aluminum Composite Material Panel ~ ALPOLIC/PE Series

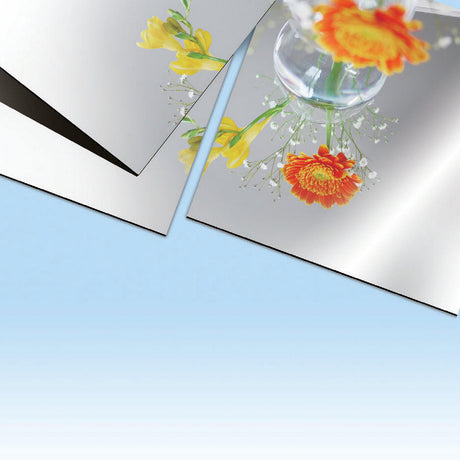

Regular price $0.00 USDUnit priceUnavailableReflective Aluminum Composite Material Panel ~ ALPOLIC/RF Series

Regular price $0.00 USDUnit priceUnavailableSignage Aluminum Composite Material Panel ~ ALPOLIC Graphic-AL Series

Regular price $0.00 USDUnit priceUnavailable

Aluminum Composite Material (ACM) Panels are a modern solution in the sign-making industry, offering a sleek, durable, and versatile option for various projects. These panels are known for their strength and lightweight design, making them ideal for both indoor and outdoor use.

Wired4Signs is proud to partner with Mitsubishi Plastics Composites America Inc., bringing the high-quality Alpolic range of ACM materials to our customers. This partnership ensures that our clients receive top-tier products with long-lasting warranties of 10, 20, or 30 years, making ACM panels a reliable and stylish choice.

What Are Aluminum Composite Material Panels?

Aluminum Composite Material (ACM) panels are lightweight, durable building materials made from two thin layers of aluminum with a core made from non-aluminum materials, like polyethylene or mineral-filled core. These panels are popular in construction because they offer excellent strength, weather resistance, and flexibility.

ACM panels are commonly used for exterior cladding, signage, and interior applications. They come in a variety of colors and finishes, making them ideal for architectural design. These panels are also known for their ability to provide thermal insulation and soundproofing while being easy to install and maintain.

Their lightweight nature reduces structural load, which is why they're a preferred choice for both new constructions and renovations. ACM panels also have fire-resistant options, making them safer for various building projects.

Applications of Aluminum Composite Material Panels

- Exterior cladding for buildings

- Interior wall partitions

- Indoor and outdoor Signage

- Exhibits stands and displays

- Framing and mounting

- Transportation vehicle interiors and exteriors

- Column covers and beam wraps

- Elevator wall panels

- Roofing and ceiling systems

Key Features of Aluminum Composite Material

-

Versatility: ACM panels are easy to cut, shape, and install with regular tools. They keep a flat appearance over time, preventing ripples or bends.

-

Lightweight and Cost-Effective: ACM panels are about half the weight of traditional aluminum, making them a more affordable option for projects needing similar thickness.

-

Durability: ACM offers great protection against UV rays, scratches, weather damage, and corrosion. It's also easy to clean, keeping its sleek, shiny look for longer.

-

Signage and Display Applications: ACM works well with traditional inks, digital printing, and adhesive print media. It's UL-approved for sign use and can even be used in electrical enclosures.

Explore Our Range of Aluminum Composite Material Panels

1. Fire-resistant ALPOLIC/fr panels are perfect for buildings needing fire safety. They feature two aluminum layers surrounding a fire-resistant core, making them ideal for high-rise and sensitive areas. These panels meet many fire safety codes worldwide, offering a range of attractive finishes and colors. ALPOLIC®/fr is a top choice for durable, fire-resistant exterior cladding, used in many significant projects globally.

2. Heavy duty ALPOLIC/HD panels are our strongest, designed for tough environments. With thicker aluminum skins and superior strength, these panels withstand heavy traffic and harsh conditions. They use advanced coatings for durability and a sleek look. ALPOLIC®/HD is perfect for demanding applications needing extra strength and resilience, yet easy to work with due to standard thickness.

3. Lightweight ALPOLIC/PE panels offer a lightweight, easy-to-install option with excellent rigidity. Made with aluminum layers around a polyethylene core, they are ideal for signage, interior walls, and lightweight exterior uses. These panels provide the durability of metal in a more manageable form, available in various finishes and colors at a competitive price.

4. Reflective ALPOLIC/RF panels feature a polished, reflective surface for striking visual effects. These lightweight panels are easy to install and durable, perfect for design and architecture where high reflectivity is needed. They offer the shine of traditional reflective materials without the weight and breakability issues.

5. Signage ALPOLIC Graphic-AL panels are designed for signage and advertising. They have a smooth surface for vivid graphics and are available in different types for various needs. Whether for indoor displays or outdoor signs, these panels provide excellent flatness, durability, and visual impact, keeping signs and displays looking great over time.

Wide Range of Color and Finishes Options Available:

The Alpolic "Standard Range" includes a wide variety of colors. If you need a custom color, Wired4Signs, working with Mitsubishi Plastics, can create any specific shade you require.

Check out the Alpolic Stock Color & Finishes Brochure

Have Questions About Aluminum Composite Material Panels?

FAQs

How long does aluminum composite panel last?

Aluminum composite panels typically last between 30 to 50 years, depending on factors like environmental conditions, quality of the material, and maintenance.

Is aluminum composite material panels waterproof?

Yes, aluminum composite material (ACM) panels are waterproof due to their aluminum layers and protective coatings, making them suitable for exterior use in various weather conditions. However, proper installation is required to ensure full water resistance at joints and edges.

Is aluminum composite material effective for sound insulation?

Yes, in addition to their durability and weather resistance, Aluminum Composite Material panels also offer sound insulation properties. The core material in ACPs acts as a barrier that absorbs and dampens sound waves, making them an ideal solution for projects where acoustic performance is important, such as in concert halls, theaters, and office spaces.

How do you install aluminum composite panels?

Aluminum composite panels can be installed using methods such as mechanical fixing, adhesive bonding, or hanging using a framing system. The chosen method depends on factors like panel size, location, and the structural requirements of the project.