-

DIN-rail 4-Channel Constant Voltage LED Dimmer with Modbus ~ Model DLD1248-4CV-MODBUS

Regular price $211.76 USDUnit priceUnavailableDIN-rail 4-Channel Constant Current LED Dimmer with Modbus ~ Model DLD1248-4CC-MODBUS

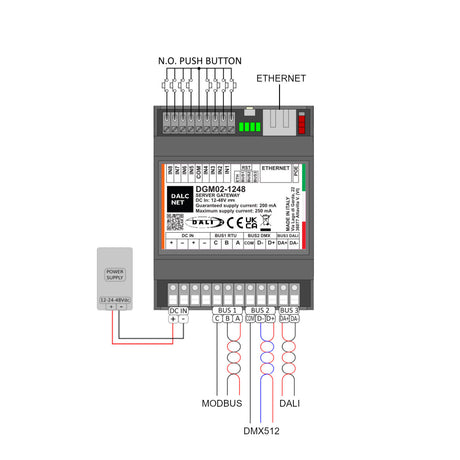

Regular price $211.76 USDUnit priceUnavailableMulti-Bus Network Gateway and Protocol Converter ~ Model DGM02-1248

Regular price $882.34 USDUnit priceUnavailable

Modbus Lighting Controllers

Modbus is a digital network command protocol for bi-directional communication between various devices. It is a widely adopted industry-standard communication protocol, making it a popular choice for lighting control applications due to its reliability and versatility.

The Modbus protocol is implemented in two forms:

- Modbus-RTU is the name for the wired serial communication bus and uses RS-485 media with a multi-drop topology.

- Mobus-TCP is the name for Modbus over Ethernet/IP networks. Modbus-TCP can be used over standard wired CAT5 and CAT6 Ethernet networks or over Wi-Fi networks.

The Modbus protocol for lighting control

The Modbus protocol is an industry standard which is widely used in many industries. Of course, this means that it is also used in the building automation field and, more specifically, for the lighting control systems.

A pivotal aspect of this integration is the utilization of dedicated lighting components like the Modbus LED controller. These components operate seamlessly within the framework of the broader Modbus protocol, enabling precise and efficient control of LED lighting systems via industry standard Modbus commands.

By leveraging a Modbus controller in conjunction with a Modbus display, users can attain a comprehensive overview of their lighting network's status and performance. The streamlined communication facilitated by the Modbus protocol enhances the synchronization between various devices, ensuring harmonious lighting management.

Dalcnet Modbus lighting controllers for sale

We stock top-quality Modbus-compatible lighting controllers from Dalcnet, designed and made in Italy. Each Modbus controller contributes to a comprehensive suite of solutions designed to elevate lighting management to new heights of precision and efficiency.

The Dalcnet Modbus range includes a versatile Modbus gateway with Ethernet, DALI and DMX interfaces as well as Mobus protocol LED dimmers and relay controllers. Within this extensive lineup, Dalcnet's LED controller Modbus range encompasses a diverse selection of products tailored to meet an array of control needs.

To read more about our diverse collection of Modbus lighting controllers for sale and related solutions, see here.

Where else are Modbus controllers used?

Modbus protocol controllers are commonly used in wide range of industries for communication between devices and systems. Some of the industries where Modbus LED protocol controllers are utilized include:

-

Industrial Automation: Modbus is widely used in industrial automation applications for connecting programmable logic controllers (PLCs), remote terminal units (RTUs), sensors, and other devices to exchange data and control processes. The versatility of Modbus extends to industrial settings, encompassing applications such as industrial LED displays. These industrial LED message displays serve as pivotal components in conveying real-time information, status updates, and critical messages across manufacturing facilities, warehouses, and industrial sites. The seamless integration of Modbus controllers ensures efficient communication within industrial environments, fostering streamlined operations and informed decision-making.

-

Energy and Utilities: Modbus is employed in the energy and utilities sector to monitor and control equipment such as meters, sensors, and power distribution systems.

-

Oil and Gas: Modbus is utilized in the oil and gas industry for supervisory control and data acquisition (SCADA) systems, enabling efficient monitoring and management of remote devices and equipment.

-

Water and Wastewater: In water treatment and wastewater management, Modbus protocol controllers are used to communicate with various components like pumps, valves, and flow meters.

-

Building Automation: Modbus finds applications in building automation systems to connect and control HVAC (Heating, Ventilation, and Air Conditioning) units, lighting, and other building equipment.

-

Manufacturing: Modbus is commonly employed in manufacturing processes to facilitate data exchange between different machines, controllers, and manufacturing execution systems (MES).

-

Renewable Energy: Modbus is used in renewable energy systems, such as solar and wind power installations, to monitor and control the generation and distribution of energy.

-

Transportation: In the transportation industry, Modbus protocol controllers can be used in control systems for trains, buses, and other vehicles to manage various components and subsystems. This extends to the realm of automotive lighting as well, where the application of Modbus shines particularly brightly as automotive LED light controller. The integration of Modbus technology facilitates precision control over automotive LED lights, allowing for advanced functionalities like automotive LED control RGBW (red, green, blue, white). Automotive LED controllers utilizing Modbus protocols enable seamless adjustments, dynamic color changes, and intricate lighting patterns that contribute to both aesthetics and safety on the road.

-

Agriculture: Modbus is utilized in agricultural applications for monitoring and controlling irrigation systems, climate control in greenhouses, and other farming equipment.

-

Telecommunications: Modbus can be found in telecommunications systems for monitoring and managing network equipment and infrastructure.

These are just a few examples of industries where Modbus protocol controllers are applied. Due to its simplicity, versatility, and widespread adoption, Modbus remains a popular choice for communication in many industrial and automation settings.

What is the structure of Modbus protocol?

The structure of the Modbus protocol follows a simple and organized format. Each message consists a function code that defines the type of operations plus the data payload for that operation. Each communication involves a Modbus master (initiating device) and one or more Modbus slaves (responding devices).

The Modbus master sends requests to the slaves, which then process the requests and send back responses containing the requested data or confirmation of the action taken. This structured approach ensures efficient and reliable communication between devices within the Modbus network, contributing to its widespread adoption across various industries.

Modbus protocol renowned for its high reliability

The Modbus protocol is well established and has garnered a reputation for its exceptional reliability, making it a cornerstone in the realm of industrial automation and lighting control. Renowned for its steadfast communication and seamless data exchange, Modbus continues to shine as a beacon of efficiency and consistency.

As businesses and industries seek dependable solutions for managing complex systems, Modbus emerges as a steadfast partner. In the domain of lighting control, this reliability extends to diverse applications, including the integration of Modbus LED displays and LED controllers on Modbus.

The seamless integration of these components into the Modbus network underscores its reliability in orchestrating nuanced lighting scenes and configurations, ultimately contributing to elevated operational efficiency and enhanced user experiences.

Marine Light Controller with Modbus Technology: Enhancing Ambiance and Functionality

Integrating the efficiency and adaptability of the Modbus protocol, marine light controllers are revolutionizing illumination within marine environments. Beyond familiar terrestrial applications, this protocol's versatility seamlessly extends to the sea, facilitating the operation of marine RGB LED controllers and marine LED light controllers.

Modbus is a familiar network aboard marine vessels and these controllers transcend mere functionality, engendering a harmonious interplay between enhanced lighting ambiance and optimized performance. Whether for navigational precision, atmospheric illumination, or elevating the vessel's aesthetic allure, marine LED controllers harness the power of the Modbus protocol to orchestrate lighting scenarios with unparalleled finesse.

This synergy of cutting-edge technology and maritime innovation exemplifies how Modbus-equipped marine LED controllers contribute to an immersive and dynamic marine experience, adapting to the ever-changing conditions and underlining their role in defining the marine journey.

Frequently asked questions

What type of cable is used for Modbus-RTU protocol?

The Modbus serial protocol typically uses twisted-pair cables and RS-485 for communication. These cables are well-suited for transmitting data over relatively long distances with minimal signal interference.

Can a Modbus lighting controller be used for wireless communication?

Yes, Modbus lighting controllers can be used for wireless communication by integrating them with appropriate wireless communication modules or technologies. Specifically, Modbus-TCP can be used over Wi-Fi networks.

What are the network standards for Modbus?

The Modbus protocol supports two different network standards: Modbus-RTU (Remote Terminal Unit) using RS-485 serial bus and Modbus-TCP (Transmission Control Protocol) on top of Ethernet networks.

What is the Modbus communication speed?

The communication speed of the Modbus protocol can vary based on the specific implementation and the network standard being used. Typically for RS-485 networks, the speed is reduced for longer bs lengths in order to avoid signal loss.

Can Modbus communicate over Ethernet?

Yes, Modbus can communicate over Ethernet using a variation of the protocol known as Modbus-TCP (Transmission Control Protocol). Modbus-TCP encapsulates Modbus-RTU or Modbus ASCII frames within Ethernet frames, allowing for communication over standard Ethernet networks.

How many Modbus registers can be read?

The number of Modbus registers that can be read in a single communication transaction depends on various factors, including the Modbus protocol variant being used and the capabilities of the devices involved. In Modbus-RTU or Modbus-TCP, a common approach is to read up to 125 registers (holding registers) in a single request-response transaction. This limit is defined by the Modbus protocol specification.