-

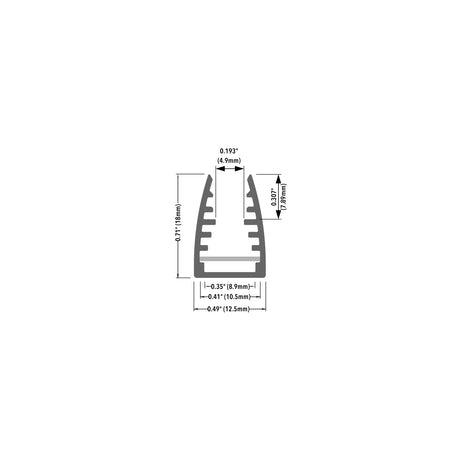

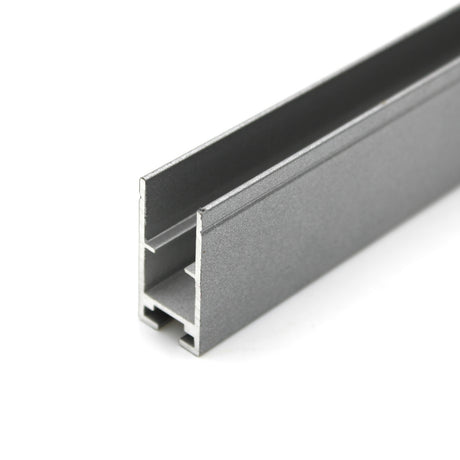

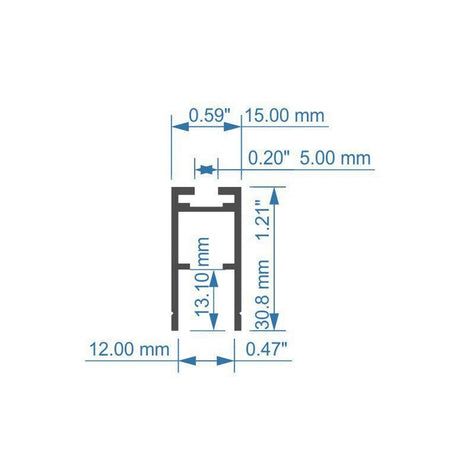

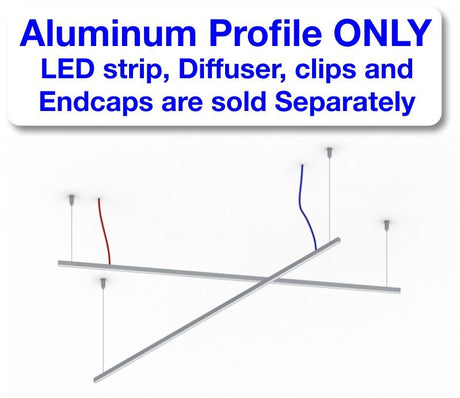

1/4" LED Edge-lit Acrylic Sign Base Channel ~ Model Mikro10

Regular priceFrom $3.28 USDUnit priceUnavailableEdge-lit Acrylic Sign Base Channel ~ Model Hannover

Regular priceFrom $3.27 USDUnit priceUnavailableEdge-Lit LED Profile for Shelves and Signage ~ Model Ginebra

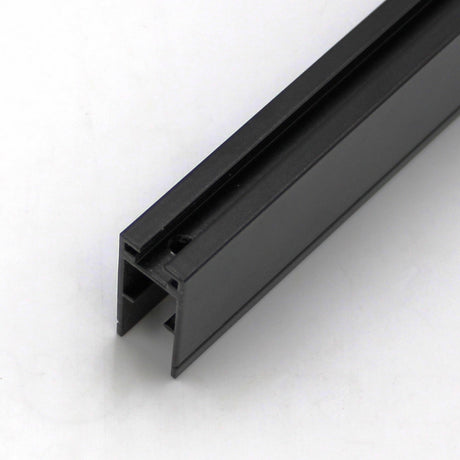

Regular priceFrom $6.89 USDUnit priceUnavailablePlastic Edge-Lit LED Channel ~ Model New Jersey

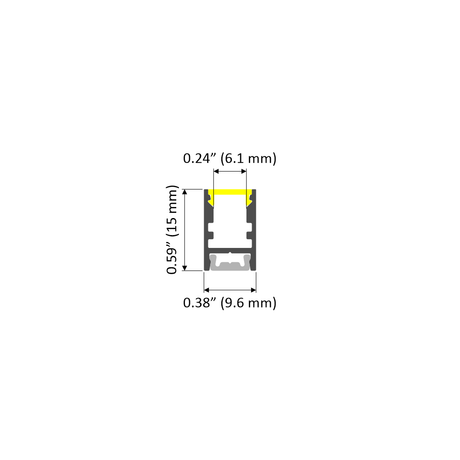

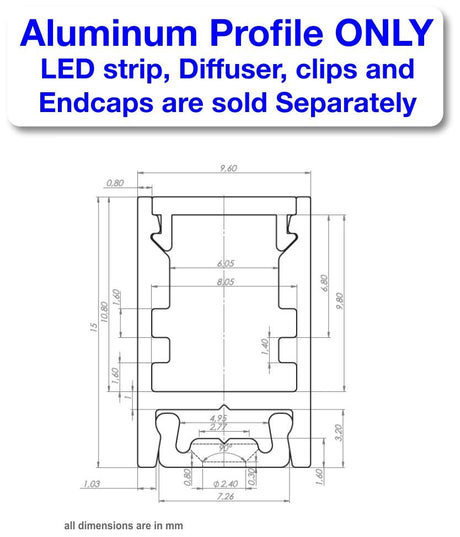

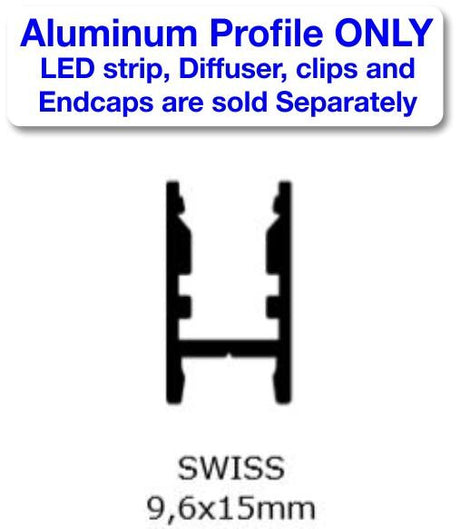

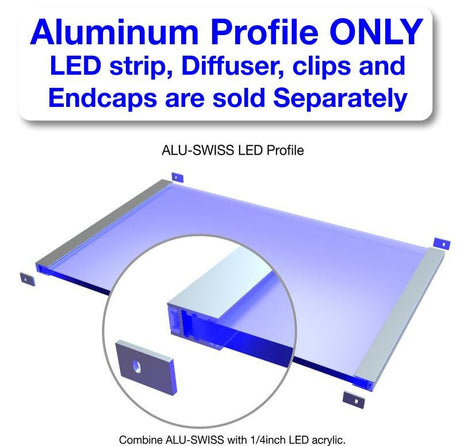

Regular priceFrom $4.68 USDUnit priceUnavailableThin Surface Mount LED Strip Channel ~ Model Alu-Swiss

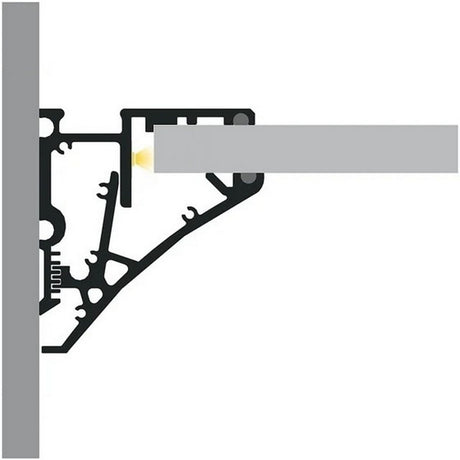

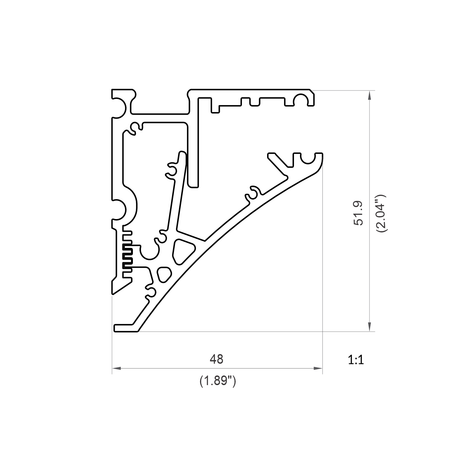

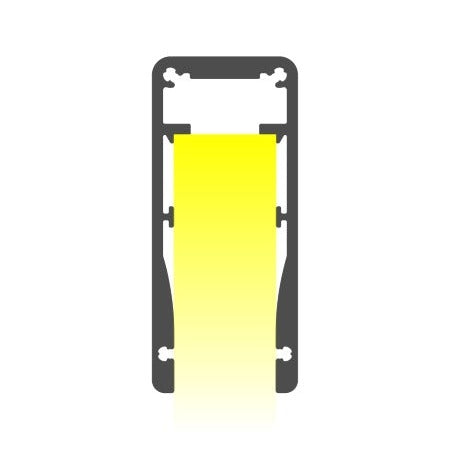

Regular priceFrom $2.67 USDUnit priceUnavailableShelf Bracket Edge-Lit LED Channel ~ Model Pula P10

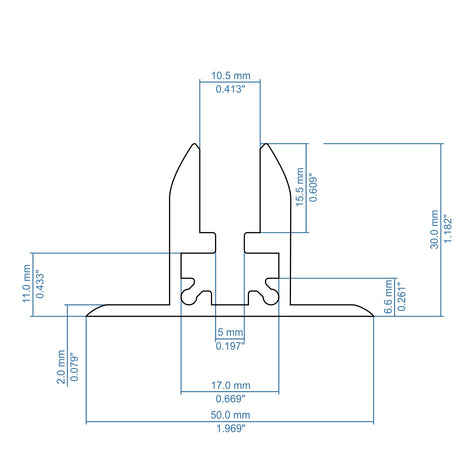

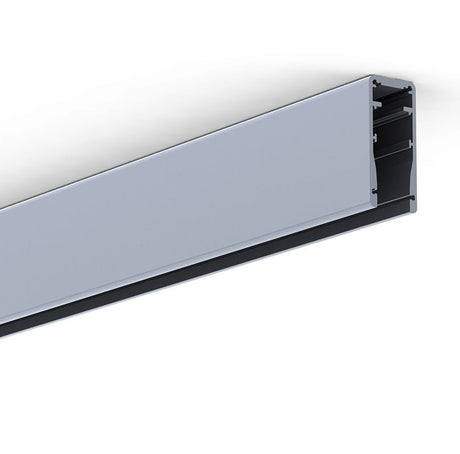

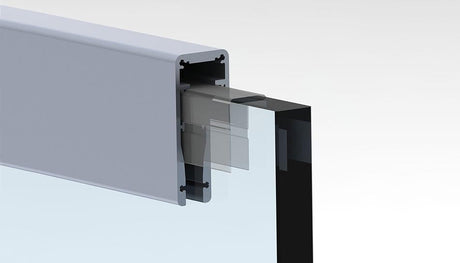

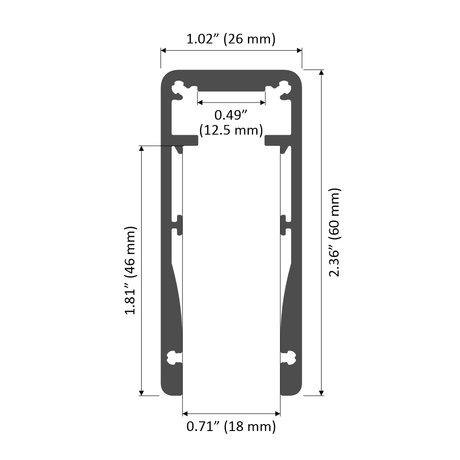

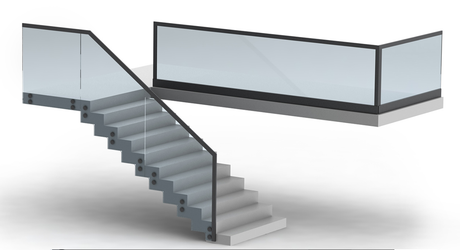

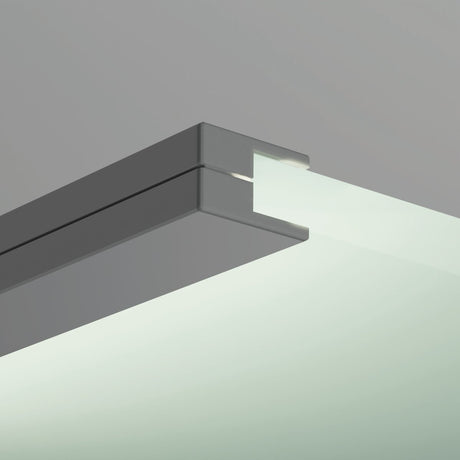

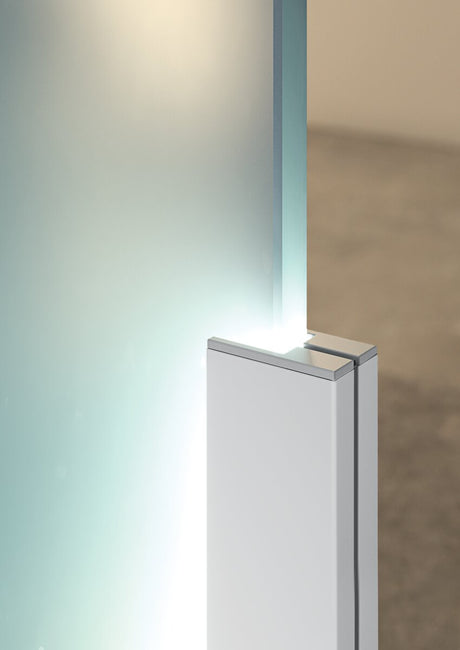

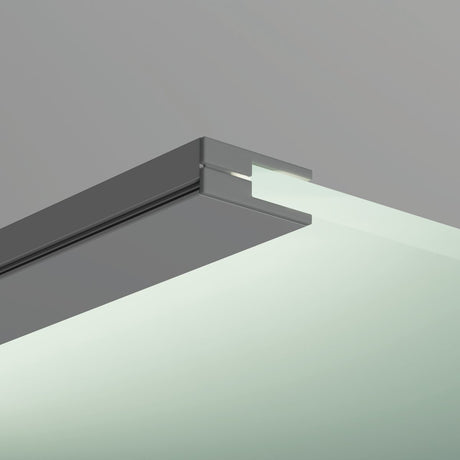

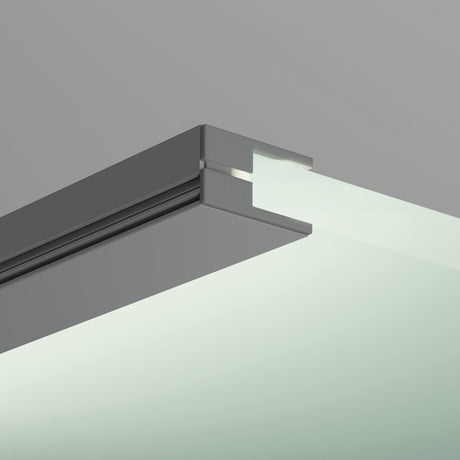

Regular priceFrom $25.50 USDUnit priceUnavailableLED Glass Railing Edge-Lit LED Strip Channel ~ Model Alu-Glass

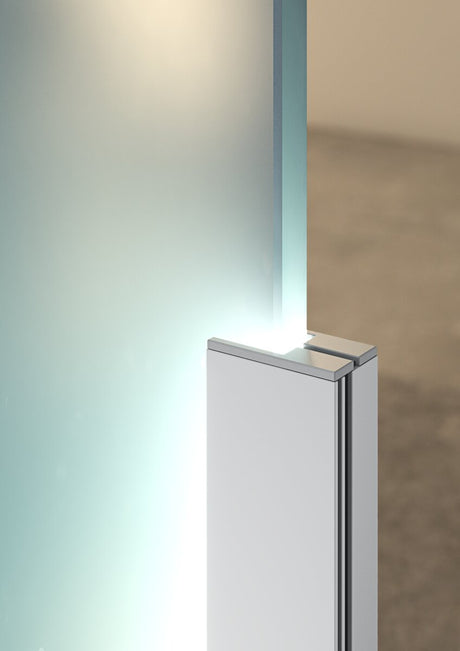

Regular priceFrom $14.50 USDUnit priceUnavailableEdge-lit LED Extrusion for 1/2" Glass Panels ~ Model Klus KRAV-05IN

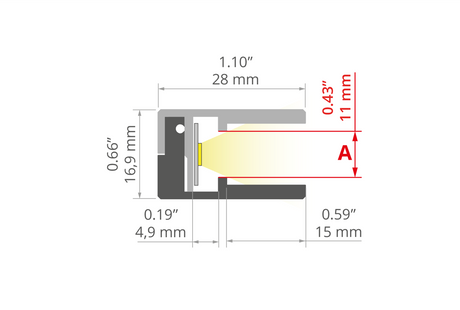

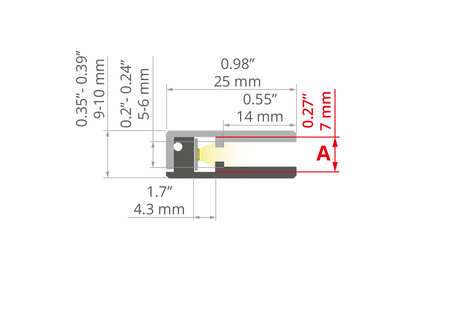

Regular priceFrom $8.95 USDUnit priceUnavailableEdge-lit LED Extrusion for 1/4" Glass Panels ~ Model Klus KRAV-56

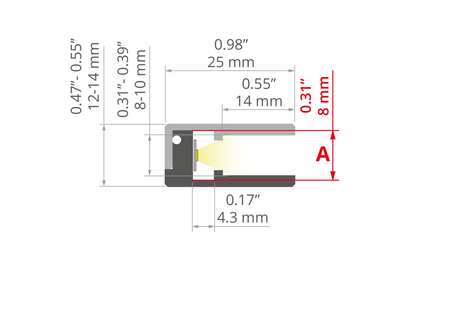

Regular priceFrom $5.90 USDUnit priceUnavailableEdge-lit LED Extrusion for 3/8" Glass Panels ~ Model Klus KRAV-810

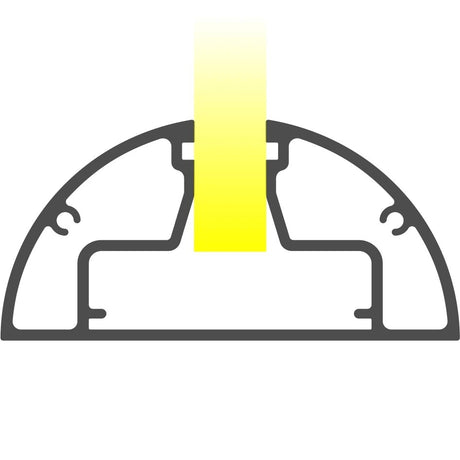

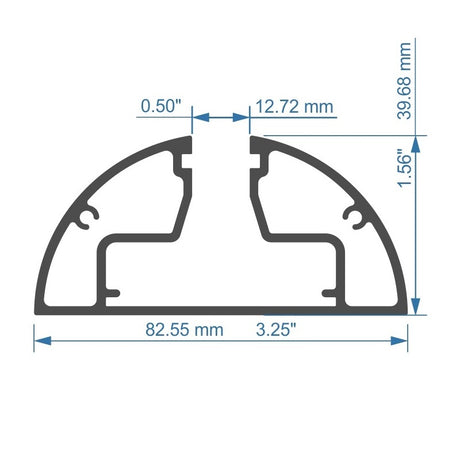

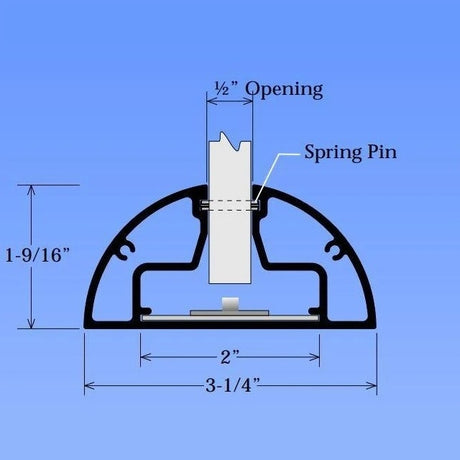

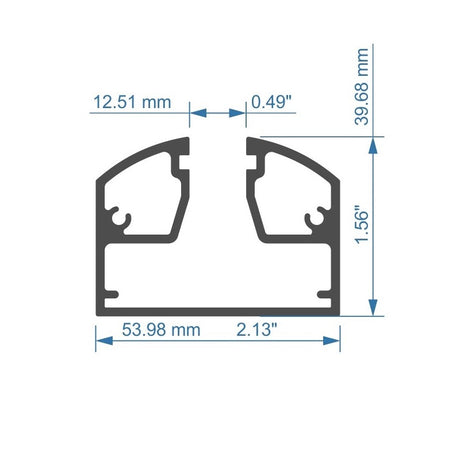

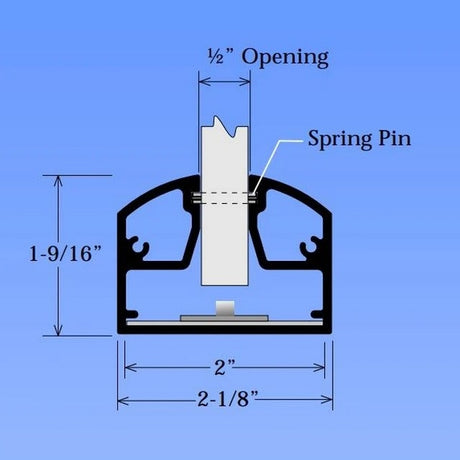

Regular priceFrom $6.49 USDUnit priceUnavailableEdge-Lit LED Extrusion for 1/2" Acrylic Signs ~ Model New York Half-Round

Regular price $42.24 USDUnit priceUnavailableGyford RGB LED Signage Standoff Kit ~ Gyford LED Standoffs

Regular price $228.46 USDUnit priceUnavailableEdge-Lit LED Extrusion for 1/2" Acrylic Signs ~ Model New York Quarter-Round

Regular price $34.63 USDUnit priceUnavailableGyford White LED Signage Standoff Kit ~ Gyford LED Standoffs

Regular price $114.22 USDUnit priceUnavailableGyford Color LED Signage Standoff Kit ~ Gyford LED Standoffs

Regular price $114.22 USDUnit priceUnavailableGyford LED Signage Standoff Expansion Kit ~ Gyford LED Standoffs

Regular price $45.68 USDUnit priceUnavailable

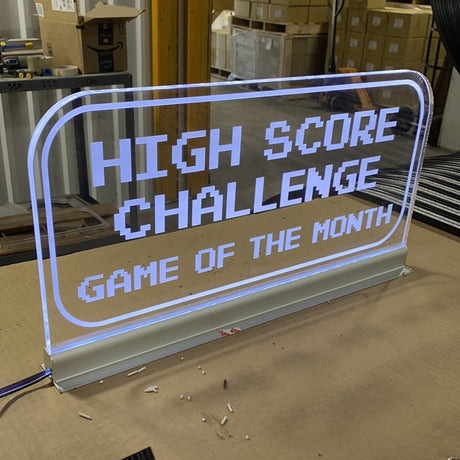

Best designs of Edge-lit LED sign kits for sale online

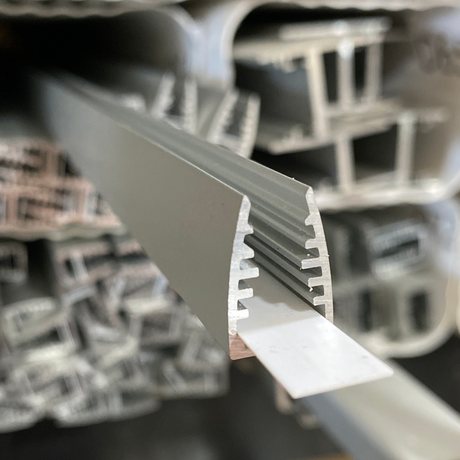

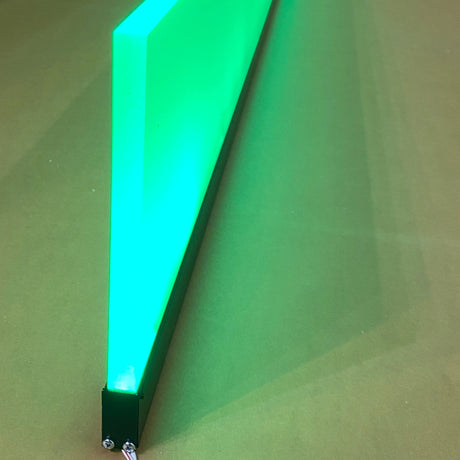

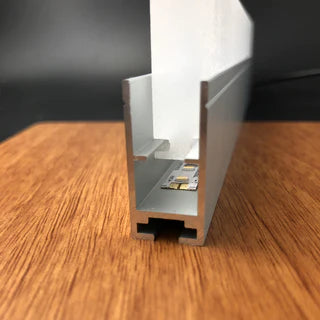

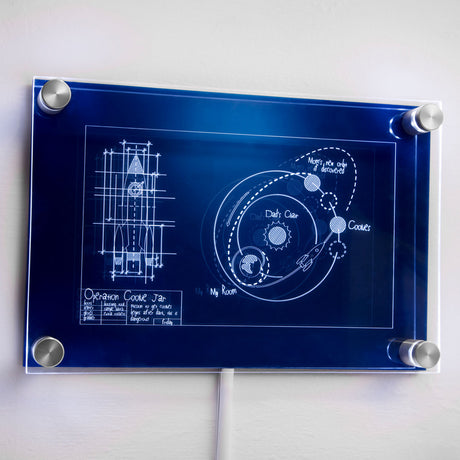

We represent some of the top European Edge-Lit channel manufacturers. Edge-lit sign kits give interior lighting in your room or residential spaces a slick modern look. LED edge-lit profiles are a great solution to lighting acrylic with LED strips, turning a simple acrylic panel into a custom LED edge-lit sign.

We stock these acrylic LED sign base channels at our warehouse in Knoxville, Tennessee, and we can ship to all parts of the USA.

What are Edge-Lit LED channels?

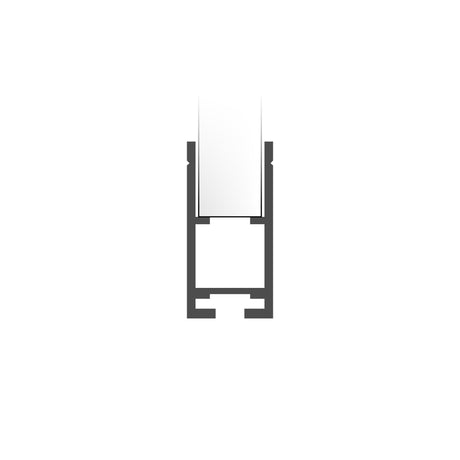

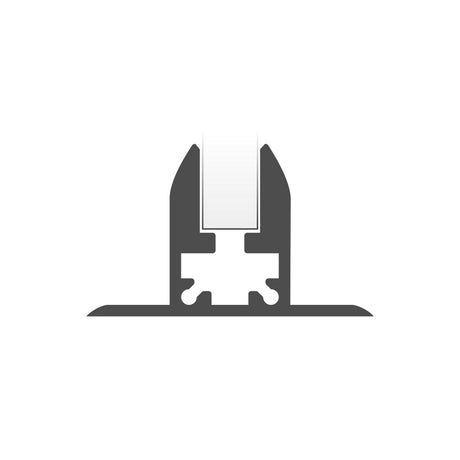

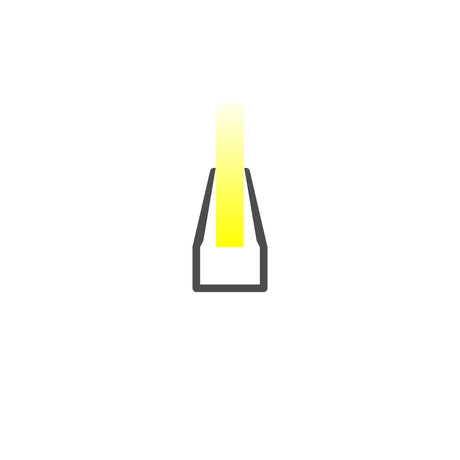

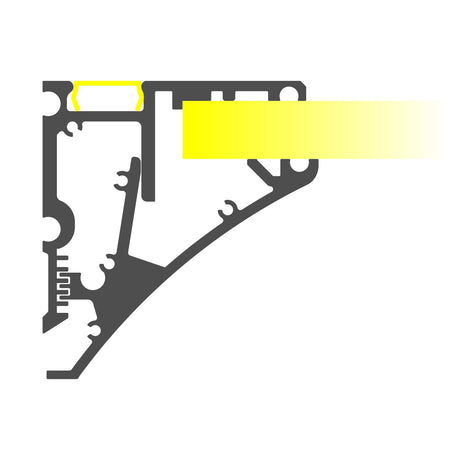

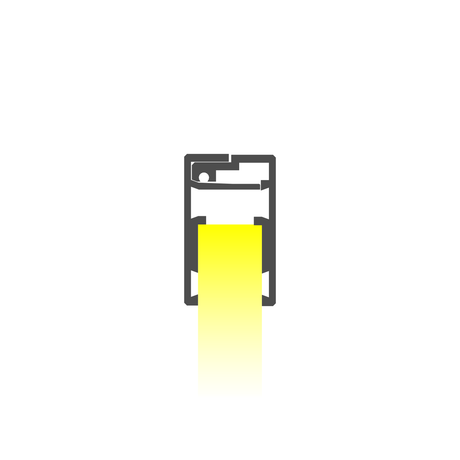

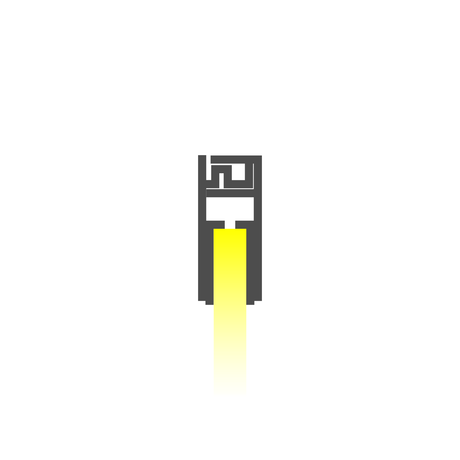

An LED base for acrylic panels is used to house LED strip lighting. Plexiglass or glass signs are typically CNC engraved, although they can also be sandblasted or laser engraved. The purpose of an Edge-Lit LED channel is to help provide :

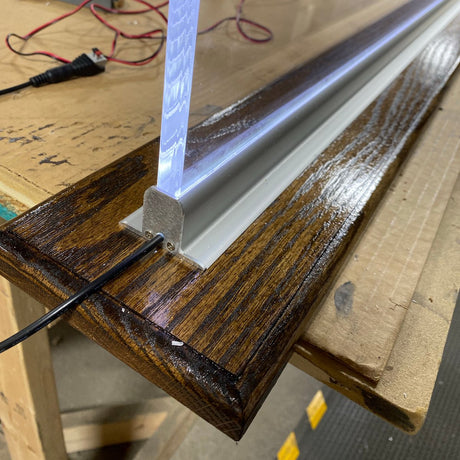

- A structure is designed to protect, accommodate, and hide the LED strips. It also functions as a heat sink for LED strips, which can extend the lifespan of any strip installed in it.

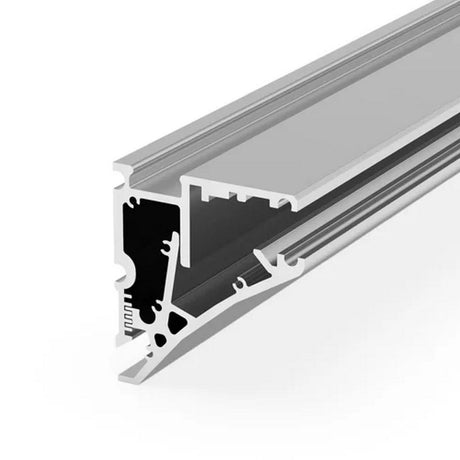

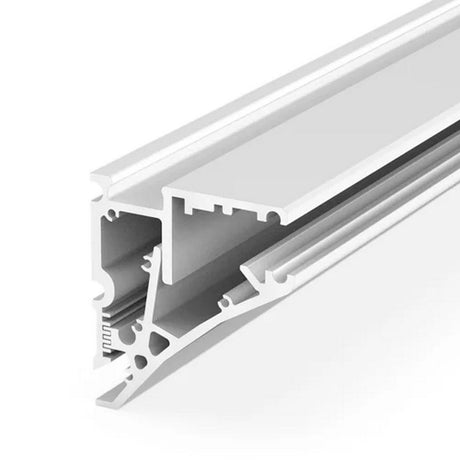

- A housing for the acrylic panels as our edge-lit LED profiles are constructed of sturdy anodized extruded aluminum.

- An attractive and innovative way of advertising your businesses and products using lighted acrylic signs.

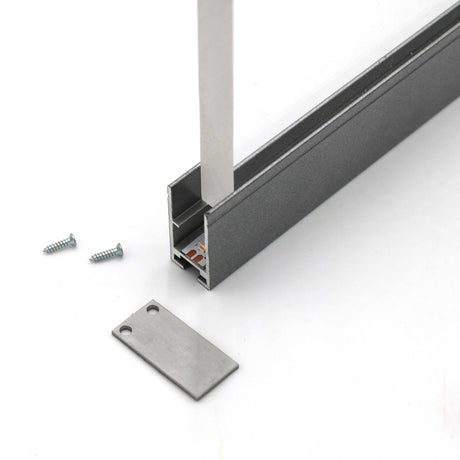

Our LED edge-lit acrylic sign base channels accessories are sold separately and consist of acrylic LED sign base, end caps, profile joiners, LED strips, and LED drivers. With these components, you can easily build a lighted sign that will beautifully showcase your brand or products.

You can cut our Edge-lit channels using a regular handsaw. Sanding after cutting the channels also refines the surface for a better finish. We can cut the Edge-lit profiles to length when required. (You can also review our detailed article on tips for cutting LED channels.)

Pros & Cons of using Edge-lit LED light bases for acrylic panels

- Edge-Lit channels with LED lighting are suited for indoor applications where you want to draw attention to an advertisement, sign, etc, using a modern fixture.

- Most of our LED strip lights are compatible with our edge-lit profiles. Always verify the width of the LED strip you want to use to make sure it will physically fit into the aluminum channel.

- Bear in mind shipping costs for linear edge-lit installations over 96 inches in length can be higher. You can overcome this by using short lengths of edge-lit profiles combined and installed next to each other for a seamless finish.

- Acrylic signs are a great way to create signs using short runs of LED strips. They are energy-efficient and easy to assemble compared to other signage lighting fixtures.

How to install Edge-lit LED aluminum channels

Detailed installation information is usually available on each edge-lit channel product description page, but these are the basic steps for setting up your installation:

- Make sure the LED strip you want to use, whether it is a Color-changing RGB, Static white, or RGB+White LED strip can fit the edge-lit LED acrylic sign base you want to install it into.

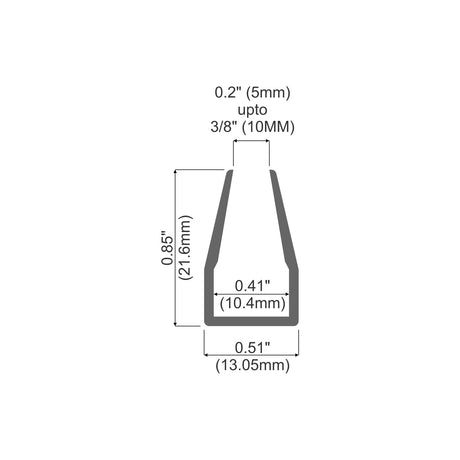

- Verify that the LED acrylic edge lighting panel width you will use can fit the edge-lit channel you want for your fixtures, some LED acrylic light bases are designed for thin panels while others can fit thicker panels.

- Using a hand or electric saw, cut the edge-lit aluminum extrusion to fit the acrylic panel you want to install. Afterward, make sure you sand the edges prior to installation.

- Insert the desired LED strip into the edge-lit panel and verify that it functions well before moving to the next step.

- Insert the acrylic panel into the LED edge-lit sign base aluminum extrusion and tighten the bolts. (Some edge-lit panels don't come with bolts but use other methods to secure the acrylic panels)

Why buy Edge-lit LED channels from us?

- Our acrylic light base channels are high quality and made in Europe or the USA.

- Our acrylic LED sign base channels which are manufactured in Europe are normally stocked and supplied from the USA.

- Some of our Edge-lit channels are available in 3-meter pieces to reduce the need for joining.

- Our agents can provide ideas and assistance for your Edge-lit LED lighting projects.

Frequently asked questions

Do Edge-lit LED profiles come complete with LED strips lights and power supplies?

No, since all projects have different specifications and energy requirements, all power supplies and LED strips are sold separately. Make sure the LED strip will fit inside the LED edge-lit base fixture.

Are edge-lit LED base fixtures dimmable?

All our LED strips are fully dimmable. You can connect a smart controller to the LED strips that you install into the edge-lit LED sign base so that you can dim, control colors, pick a favorite ambiance, then set it, and forget it. You can also create an acrylic LED light base with a wireless remote so that you can change colors or dim the lights whenever you want. Customize your man cave, create modern-looking bar signs, create your own LED night light, etc.

I have a custom project in mind, can I send the specific aluminum channel lengths to you to get it cut to size, and will there be a charge?

No, there is no charge for cutting the edge-lit acrylic bases. All you need to do is either insert the information into the order comments or contact one of the staff on the live chat with your requirements.

I am looking for good ideas as to where to use an edge-lit LED sign kit for my business. Can you help me?

If you're looking to create a highly customized look, Edge-lit LED panels are ideal for that purpose. Signs, inscriptions, acrylic light stands, LED edge-lit glass U-channel fixtures, and custom logo illumination can easily be done for your business. LED edge-lit glass channels with custom panel designs are often used as a substitute for frosted glass due to the full range of customization and finishing options.

What are the advantages of using LED technology for edge-lit acrylic displays?

LED technology offers several advantages for edge-lit acrylic displays. It provides energy efficiency, longer lifespan, and low heat output compared to traditional lighting. LEDs also allow for a more compact design, offering flexibility in display thickness. Their uniform light distribution enhances the clarity and brightness of the acrylic, making colors and details more vivid. Additionally, LEDs are more environmentally friendly, requiring less maintenance and offering better control over brightness and color.

What causes uneven illumination or bright edges (corona effect) in my display?

Uneven illumination or bright edges (known as the "corona effect") in displays are often caused by light diffusion issues, improper backlighting, or screen manufacturing defects. Common reasons include:

- Backlight Bleeding: Light leaks around the edges of the display, especially in LCDs, where the light source is unevenly distributed.

- Improper LED Placement: In displays with edge-lit LED technology, poor alignment of LEDs can cause bright edges.

- Panel Uniformity Issues: Variations in panel thickness or quality during production can result in uneven light distribution.

- Poor Diffusion: Inadequate light diffusion layers that scatter light unevenly can also contribute to this effect.

How should I install an LED light base for my acrylic display?

To install an LED light base for your acrylic display, follow these steps:

- Prepare the Acrylic Display: Ensure that your acrylic display is clean and free from dust or fingerprints. Mark the area where the LED base will be placed, ensuring it aligns with the display for even lighting.

- Choose the Right LED Light Base: Select an LED light base that suits the size of your acrylic display. Look for one that provides sufficient illumination without creating harsh shadows. The base should be low-profile for a sleek appearance.

-

Install the LED Light Base:

- If the LED base is powered by a plug-in adapter, place the base in the designated spot at the bottom of the acrylic display.

- If it's a battery-operated base, ensure the battery compartment is easily accessible for future replacements.

- Position the base so that it is level and stable, providing uniform light distribution.

- Wire Management (If Necessary): If your LED base requires external wiring, neatly organize the cables to avoid clutter. Use adhesive clips or cable ties to secure the wires along the back or sides of the display.

- Connect the Power Source: Plug the LED base into a nearby outlet or insert batteries, depending on the model. Make sure the power source is easily reachable for turning the lights on and off.

- Test the Lighting: Once everything is connected, power on the LED base. Adjust the brightness or angle of the light if necessary to ensure the display is evenly lit without harsh glares or shadows.

How do I maintain my LED light base and acrylic display?

To maintain your LED light base and acrylic display, follow these simple steps:

- Regular Cleaning: Use a soft, lint-free cloth to gently wipe the acrylic surface. For stubborn dirt, use a mild soap solution or acrylic cleaner. Avoid abrasive materials to prevent scratching.

- Keep Dry: Ensure both the LED base and acrylic are dry after cleaning to avoid water spots or potential damage to the electrical components.

- Avoid Direct Heat: Keep the LED light base and acrylic away from excessive heat sources to prevent warping or damage.

- Power Off When Not in Use: Turn off the LED light when not in use to extend the lifespan of both the LEDs and the acrylic display.

- Check for Dust: Periodically check for dust accumulation on the LED components, and carefully remove it with a soft brush or air blower.

Can I use different thicknesses of acrylic with standard LED bases?

Yes, you can use different thicknesses of acrylic with standard LED bases, but it’s important to consider a few factors. Thicker acrylic may reduce light output due to increased light diffusion and potential heat retention. Thinner acrylic allows for better light transmission but may not be as durable. Ensure the LED base is compatible with the acrylic's thickness to avoid overheating and ensure optimal light performance.

What should I consider when choosing an LED light base for my acrylic display?

When choosing an LED light base for your acrylic display, consider the following key factors:

- Brightness and Light Temperature: Ensure the LED base provides adequate brightness for your display and the right color temperature (warm or cool) to enhance the acrylic's appearance.

- Size and Fit: The base should match the dimensions of your acrylic display, ensuring proper support and an even light spread.

- Energy Efficiency: Choose an LED light base that is energy-efficient to minimize power consumption while maintaining optimal lighting.

- Color Rendering: A high Color Rendering Index (CRI) will ensure that the colors of your acrylic display are shown accurately.

- Heat Management: LED lights generate less heat than traditional bulbs, but ensure the base has proper heat dissipation to prevent any damage to your acrylic.

- Durability and Design: Select a base that is robust, with a design that complements your display while being easy to maintain.

- Power Source: Consider whether the base is battery-operated, USB-powered, or requires a direct plug-in, depending on your display setup and portability needs.