Power Distribution using Wago Connectors for LED Strip Lights: A Comprehensive Guide

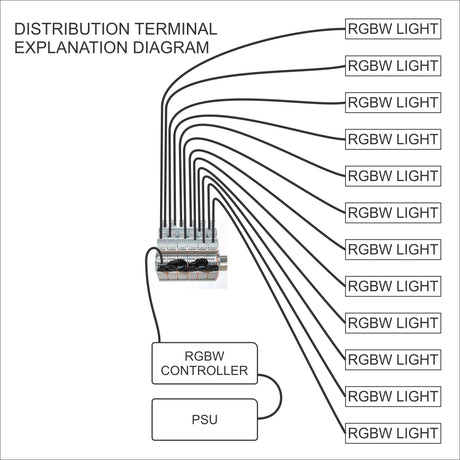

What is power distribution? Power distribution refers to the process of supplying electrical power from a source to various devices or components, such as LED light strips. LED light strips require a consistent and stable supply of power to function efficiently and produce the desired lighting effect.

Proper power distribution is very important for ensuring the safe and efficient operation of LED strip lights in various applications, like in accent lighting, task lighting, and architectural lighting. However, achieving reliable and compact power distribution can be challenging, especially in space-constrained environments.

One effective solution is to use connectors specifically designed for LED strip lights, which allow for efficient power distribution while optimizing space and reducing installation costs. Wired4signs USA offer a compact, easy-to-use, and reliable solution for distributing power to your LED strips. This comprehensive guide will walk you through everything you need to know about using our connectors for LED strip light power distribution, from selecting the right components to installation and troubleshooting.

Understanding the Use of Power Distribution in LED Strip Lights

LED light strips need consistent power supplied to each individual LED to prevent issues like uneven brightness, flickering, or burnout. Proper power distribution is achieved by using specialized connectors, terminal blocks, and power taps designed for LED strips. These components regulate the current and voltage to evenly distribute power along the entire strip length.

Installers can use parallel or series wiring techniques with compatible connectors to prevent voltage drop, overheating, and premature failure. Correct power distribution ensures even illumination, prolongs the lifespan of LED strips, enables safe installations, and maximizes energy efficiency.

Types of Connectors for LED Strip Lights

Connectors for LED strip lights are available in two main categories: wired connectors and pluggable connectors. Wired connectors, such as soldered or crimped connections, provide a permanent electrical connection but require more labor-intensive installation. Pluggable connectors, like quick-connect or terminal blocks, offer a convenient and modular approach, allowing for easy installation, maintenance, and reconfiguration.

Selecting the Right Connectors

Selecting the right connectors is a crucial step in ensuring proper power distribution and optimal performance for LED strip light installations. At Wired4Signs, we offer a wide range of connectors to meet various application requirements, including the versatile WAGO connectors, featuring both wire lever-nut and pluggable options.

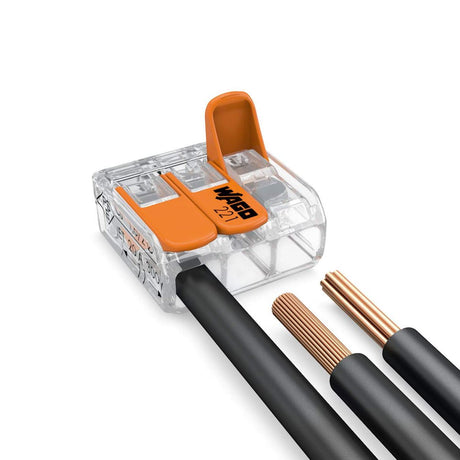

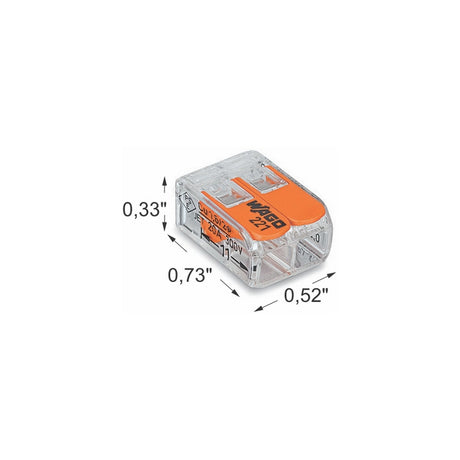

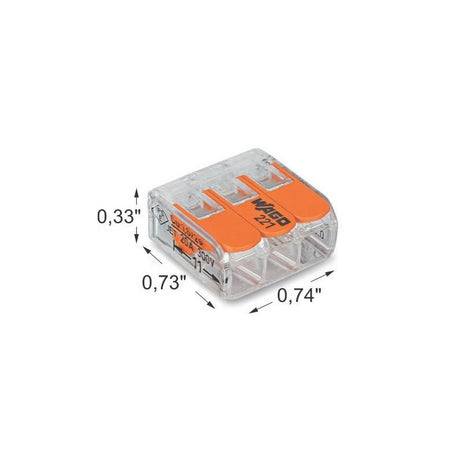

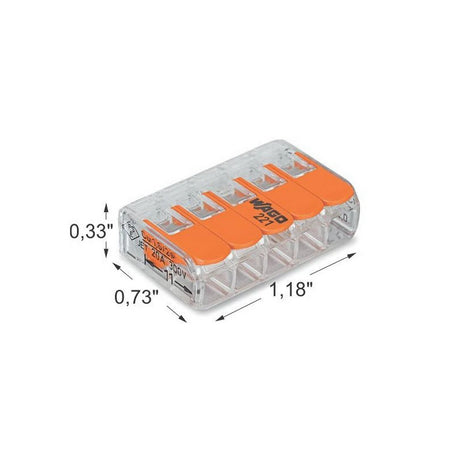

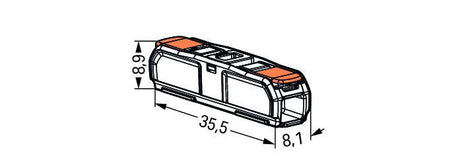

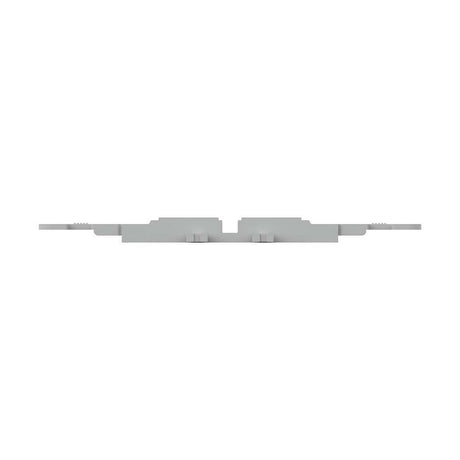

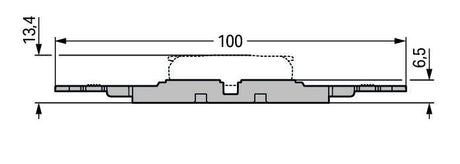

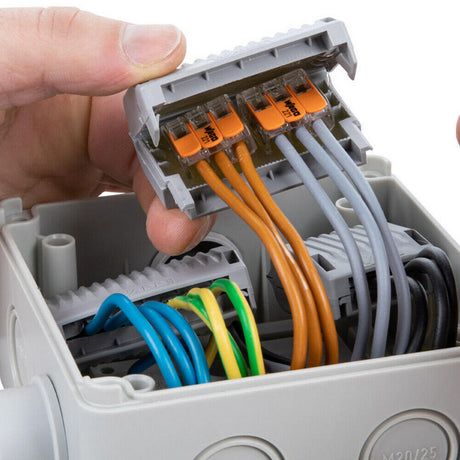

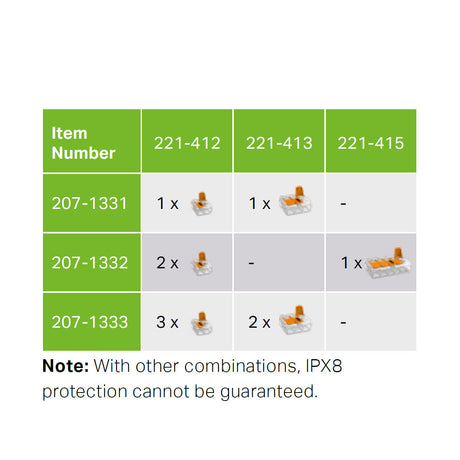

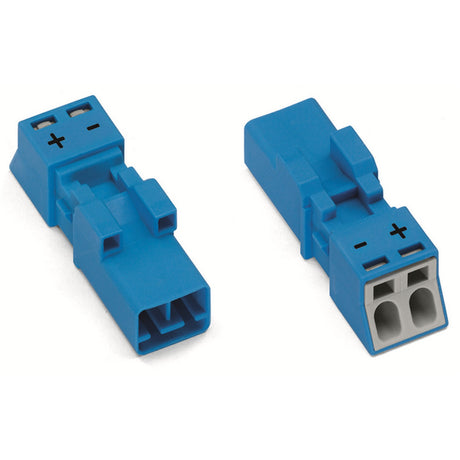

WAGO connectors are renowned for their ease of use, reliable connections, and compact design, making them an excellent choice for LED strip light projects. The wire lever-nut connectors like the Wago 221 Series Multi-Wire Splicing Lever-Nut Connector and Inline Wire Splicing Lever-Nut Connector which allow for tool-free termination of solid or stranded conductors, while the pluggable connectors like the Wago 890 Series Pluggable Connector offer a convenient modular approach for quick installation and maintenance. Both of them are suitable for longer runs or when multiple power sources are required.

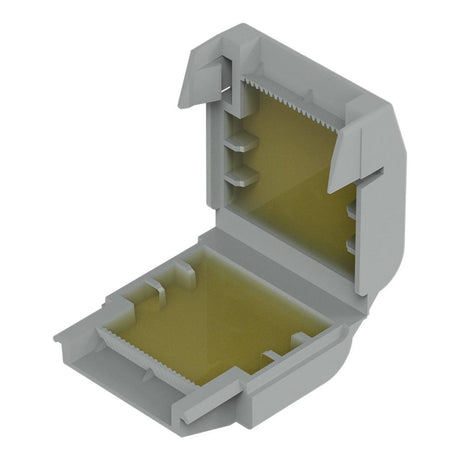

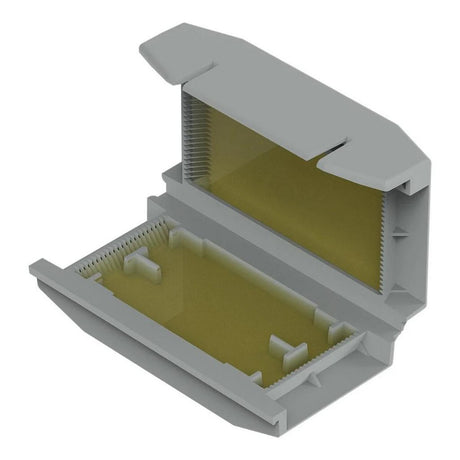

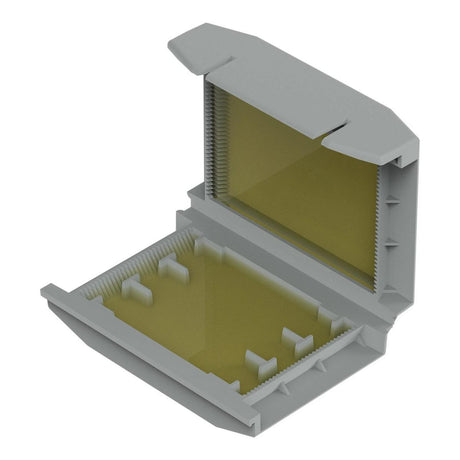

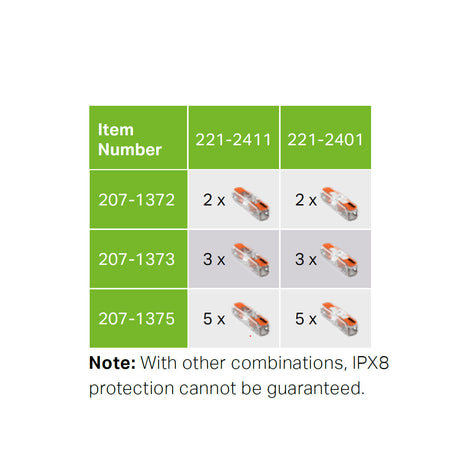

In addition to our WAGO connectors, we also provide waterproof sealing GEL-Boxes and junction blocks. These enclosures protect the connections from moisture, dust, and other environmental factors, ensuring long-lasting and reliable performance in outdoor or harsh environments.

With our extensive selection of connectors and accessories, you can be confident in finding the right solution for your LED strip light project, whether it's for residential, commercial, or industrial applications. Our knowledgeable team is always available to assist you in selecting the appropriate components and providing guidance on installation best practices.

Choosing the Right Wago Connectors for Power Distribution

To ensure safe and efficient power distribution, it's important to choose the right Wago connectors for your LED strip lights. You'll need to consider factors like the current rating, wire gauge, and the number of conductors you need to connect. Carefully match the connectors to your LED strip light requirements and calculate the power needs and connector capacity to ensure proper operation.

Installation and Wiring Guidelines

Proper installation is key to ensuring the longevity and performance of your LED strip light system. We provide a comprehensive instructions for each connector you need, to guide you through preparing the LED strip lights and wiring, connecting the Wago connectors, and mounting and securing them in place. You can also download it to our website and follow these steps carefully for a seamless installation process.

Troubleshooting and Maintenance

Even with proper installation, issues like flickering, dimming, or complete failure may occur over time. Understanding common problems and their troubleshooting steps can help identify and resolve issues quickly. Regular preventive maintenance, such as inspecting connectors and tightening terminal connections, can extend the lifespan of your power distribution system. When necessary, upgrading or modifying existing installations with newer components can improve performance and efficiency.

Using connectors for power distribution in LED strip light installations offers numerous benefits, including improved reliability, increased flexibility, and optimized space utilization. Proper planning, selecting compatible connectors, and following best installation practices are essential for ensuring safe and efficient operation.

Explore Wired4Signs' range of high-quality connectors and power distribution solutions to enhance your LED lighting projects.

Frequently Asked Questions

Are LED strip connectors rated for high currents?

No, LED strip connectors are typically not rated for high currents. They are designed for low-voltage applications and are best suited for the specific voltage and current requirements of LED light strips.

Is it possible to use Wago connectors with stranded wire?

Yes, it is possible to use Wago connectors with stranded wire. You can choose the appropriate range that suits your application and ensure compatibility with the CSA of your wire gauge. It's worth noting that some series of Wago connectors are designed exclusively for solid conductors.

What is the power rating of Wago connectors?

The power rating of Wago connectors can vary depending on the specific model and application. To determine the power rating of a Wago connector you need, you can refer to the product datasheet or specifications we provided to our website.

Can you use WAGO connectors on a lighting circuit?

Yes, these connectors are commonly used in electrical installations for their reliability, ease of use, and versatility.

Can WAGO connectors be used on 120V?

Yes, WAGO connectors can be safely used on a 120V electrical circuit. But make sure that the specific WAGO connectors you're using are rated for the voltage of your application to maintain safety and prevent any electrical hazards. Always refer to the product specifications and guidelines provided for proper usage.

What is the best power distribution solution for LED lighting installations?

The best power distribution solution for LED lighting installations is a centralized low-voltage power supply system with dedicated LED drivers and DMX or DALI control, ensuring efficient power management, reduced voltage drop, and precise lighting control.

Can I use your power distribution systems for both 12V and 24V applications?

Yes, our power distribution systems support both 12V and 24V applications.

Are your power distribution blocks UL listed or certified?

Yes, our power distribution blocks are UL listed, meeting UL safety standards for electrical distribution components.

What are the benefits of using DIN rail-mounted power distribution blocks?

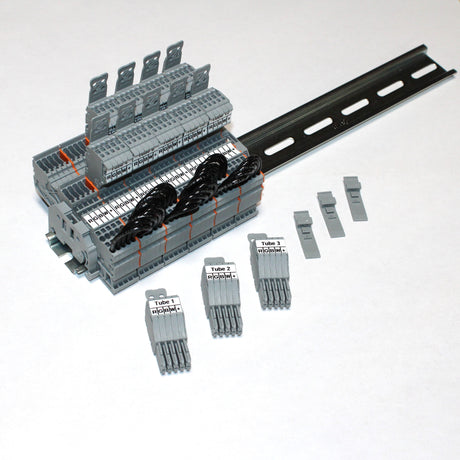

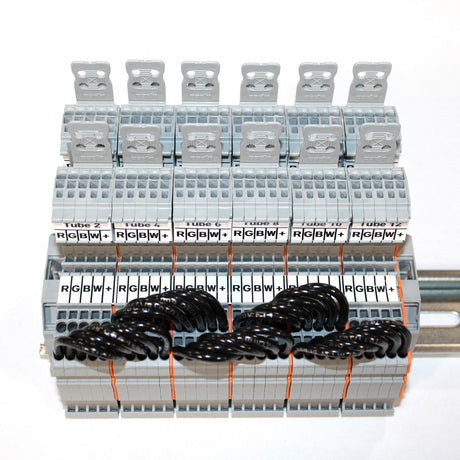

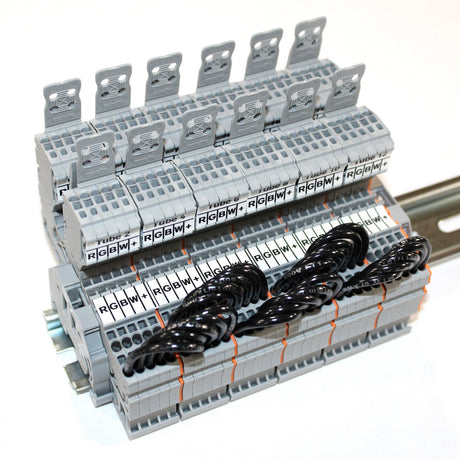

DIN rail-mounted power distribution blocks offer quick and efficient installation. Their compact design optimizes space and ensures organized wiring within control panels. They provide secure and clearly defined terminal points for safe and reliable connections. These blocks support flexible configurations and easy system expansion. They also simplify maintenance and troubleshooting by improving accessibility and clarity.

How do I choose the right power distribution block for my project?

To choose the right power distribution block for your project, consider the following:

-

Current Rating – Match the block’s amp rating to the maximum current your system will draw.

-

Voltage Rating – Ensure it supports your system’s voltage.

-

Number of Circuits – Choose based on how many outputs you need.

-

Wire Size Compatibility – Check the block supports the wire gauges you're using.

-

Mounting Type – Pick a block that fits your space and mounting setup (DIN rail, panel, etc.).

-

Environment – Use a block rated for your conditions (e.g., heat, moisture, vibration).

Always follow local electrical codes and the given manufacturer specs.

How do I install a power distribution block safely?

To install a power distribution block safely, follow these steps:

-

Turn Off Power: Ensure all power sources are disconnected before starting. Lockout/tagout if necessary.

- Choose the Right Block: Select a block rated for the voltage and current of your system. Verify it has appropriate insulation and terminal spacing.

-

Mount the Block: Secure the block on a non-conductive surface using screws or DIN rail, ensuring it’s accessible and free from vibration or moisture.

- Mount the Block: Secure the block on a non-conductive surface using screws or DIN rail, ensuring it’s accessible and free from vibration or moisture.

- Strip Wires Properly: Strip insulation to the manufacturer’s recommended length—usually 10–12 mm. Avoid nicking the conductor.

- Insert and Secure Wires: Insert the main feed wire into the input terminal and branch wires into output terminals. Tighten all screws to the specified torque. Use a torque screwdriver.

- Check Connections: Tug test each wire gently to ensure secure connections. Confirm there are no stray strands or loose wires.

- Insulate as Needed: If the block is not fully enclosed, install a protective cover or place it inside an electrical enclosure to prevent accidental contact.

-

Restore Power and Test: Once everything is secure and double-checked, restore power and test voltage at all output terminals.