Date: June 16, 2025

Wiring LED strips might seem straightforward, but common mistakes can result in poor performance, flickering, shortened lifespan — or worse, safety risks like arcing and fire.

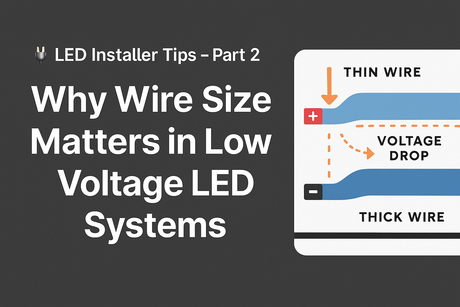

🚫 Mistake #1: Undersized Wire Gauge

Using wire that’s too thin for the current draw causes heat, voltage drop, and potential failure. Refer to the 3% voltage drop charts to select proper wire gauge. Don’t use the same gauge for AC and DC sides of the power supply — DC requires thicker wire for safe, stable current flow.

🔥 Mistake #2: Shared Return Loops

Connecting multiple LED strips with a shared return loop may seem clever, but it can cause unpredictable voltage imbalance, overloading, and erratic behavior. Always provide dedicated return paths and keep polarity consistent across all runs.

⚠️ Mistake #3: Arcing from Loose or Inappropriate Connectors

Do NOT use screw-tighten “chocolate block” connectors or twist-on wire nuts. These can loosen over time or be overtightened, damaging wire strands and creating arcing hazards. Instead, use Wago 221 lever connectors — they provide secure, gas-tight connections that are safe and reusable.

💡 Bonus Tip: Always Fuse Your Circuits

A common oversight is wiring long LED runs without fuse protection. Every feed circuit should include an inline fuse or breaker sized slightly above your expected current draw. This protects your wiring — not just the PSU — from overload or short-circuit damage.

✅ What To Do Instead

- Use proper wire sizing based on length and current

- Keep polarity correct and feed long runs from both ends

- Use Wago 221 or equivalent high-quality lever connectors

- Fuse every LED circuit

- Seal connections properly with ATV-safe silicone, not over the LEDs

🔗 Related Resources

- Part 1: Choosing the Right PSU

- Part 2: Why Wire Size Matters

- Part 3: Connector Safety

- Part 4: PSU Mounting & Cooling

- Part 5: Silicone and LED Damage

- Wiring Accessories Collection

Our in-house electronics professor has seen it all — these rules are based on years of real-world troubleshooting and installs gone wrong. Get it right the first time.

➡️ Coming Up Next

Part 7: Feeding Long LED Strips – Voltage Drop, Dual Feeds & Segment Rules

Learn how to prevent dimming, flicker, and overload by powering strips the right way across longer distances.