Good wiring won’t save you if your connectors fail. Poor contact, arcing, or a loose wire can undo everything — and pose a serious fire risk.

⚠️ The Hidden Dangers of Chocolate Blocks and Wire Nuts

❌ Screw-type Terminal Blocks (“Chocolate Blocks”)

These rely on tightening a screw onto the wire. They’re outdated and dangerous for LED strip installs.

- Stranded wire gets crushed — leads to poor contact

- Screws loosen over time = arcing and flickering

- Zero strain relief — wire can pull out easily

- Fire risk increases at higher current (12V/24V systems)

❌ Wire Nuts (Twist-on Connectors)

Common in AC work, but poorly suited to low-voltage DC LED applications.

- Best for solid-core wire — poor grip on stranded

- Can loosen over time, especially with vibration

- Don’t apply consistent pressure across all wires

- Only use gel-filled wire nuts outdoors and only where absolutely necessary

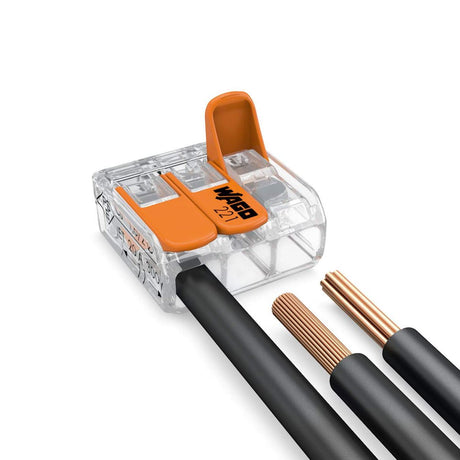

✅ Use Wago 221 Lever Connectors – Every Time

We only recommend and stock Wago 221 series connectors — for good reason:

- Spring-loaded clamps maintain solid contact over time

- Works with both solid and stranded wire

- Clear housing lets you verify correct insert depth

- No tools required — reliable, fast, and code-compliant

Other common field problems

🧰 Recommended Accessories

We stock all the connectors and tools you need for pro installs:

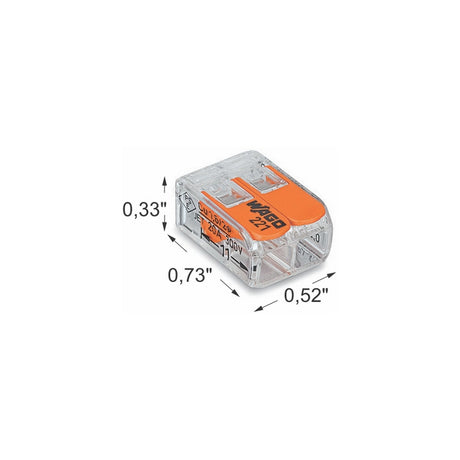

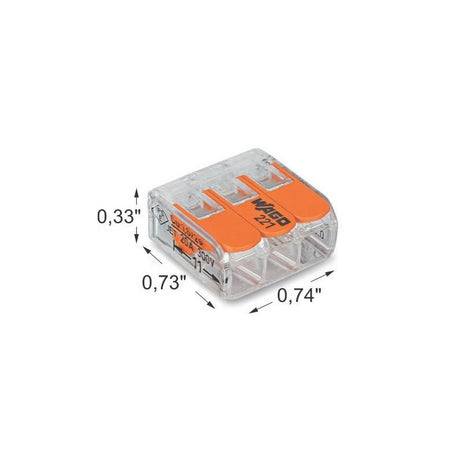

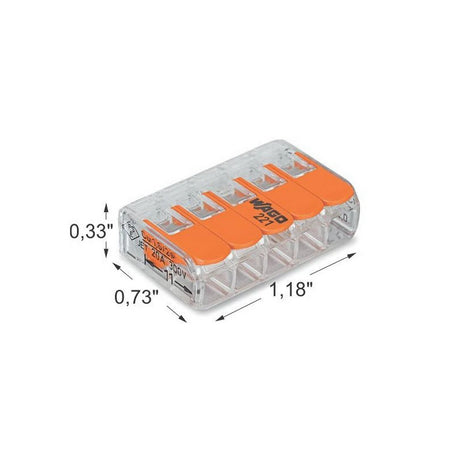

- Wago 221 lever-nut connectors in 2-, 3-, and 5-port

- Wago waterproof gel-filled lever-nuts housings (for outdoor use)

- IP-rated cable enclosures and junction boxes

Browse LED Wiring Accessories →

🔥 Real Risks of Cheap Connectors

- Melting plastic due to loose contact and high resistance

- Arcing inside chocolate blocks = invisible heat buildup

- Flickering, dimming, or total system failure

📸 Watch for Our Next Post:

We’ll show you how to identify connector failures before they happen — and how to correct wiring without redoing your install.

Next up → Part 4 – Mounting, Cooling & Wiring Your PSU Correctly