LED strip lights are a modern lighting solution known for their efficiency, flexibility, and variety of applications.

Creating these versatile lighting products involves several components and manufacturing steps that ensure high-quality output.

From understanding the core elements like SMD LEDs and flexible circuit boards to the intricate manufacturing process, this guide delves into how LED strips are made and what affects their performance.

What Are the Components of LED Strip Lights?

To produce functional and durable products, LED strip light manufacturers use several critical components to produce functional and durable LED strip lights. Each plays a unique role in ensuring the strips' performance, longevity, and flexibility.

SMD LED Diodes

SMD (Surface-Mount Device) LEDs are the primary light sources in LED strips. These diodes emit bright and consistent light, and their compact size allows for close placement along the strip, measured as LEDs per meter.

This spacing impacts the overall light output and ensures uniform illumination. The type and color temperature of the diodes determine whether the strip produces warm white light or vibrant hues for decorative purposes.

PCB Board

The printed circuit board (PCB) serves as the backbone of LED strips. High-quality PCB boards, often made from a flexible circuit board material, ensure durability and heat dissipation.

Flexible circuit boards allow the LED strips to bend and adapt to different installations, making them ideal for a wide range of applications. Proper PCB design also minimizes voltage drop, maintaining consistent brightness across the strip.

Soldered Wiring

Soldered wiring connects the SMD LEDs to the PCB board and electrical components. Precision soldering, often done by advanced pick-and-place machines, ensures strong connections that withstand regular handling.

This step is critical to ensuring the LEDs receive the proper electrical current for optimal performance.

LED Strip Lights Manufacturing Process

The production of common types of LED strip lights involves a series of precise and automated steps to guarantee quality. It begins with preparing the flexible circuit board, which is cut and treated to accommodate the SMD LEDs.

Using pick-and-place machines, manufacturers place the LED chips and other electrical components onto the board.

Next, the assembly undergoes a reflow oven process, where solder paste melts to secure components firmly to the PCB. Once assembled, the strips undergo rigorous testing to check for defects, light output consistency, and color temperature accuracy.

Finally, the strips are cut into customizable segments, often measured in feet of LED strip, for consumer use.

How Do LED Light Strips Get Power?

LED strips rely on a dedicated power supply to operate effectively, converting electrical energy into the necessary form for illuminating the LEDs.

Most LED strip lights require a low-voltage external power source, typically delivered through 5V, 12V, or sometimes 24V adapters, depending on the strip's specifications.

These power supplies serve as a bridge, transforming standard household AC power into a safer, low-voltage DC suitable for LED operation. This conversion not only protects the LEDs from potential damage caused by high voltage but also ensures consistent and reliable performance over time.

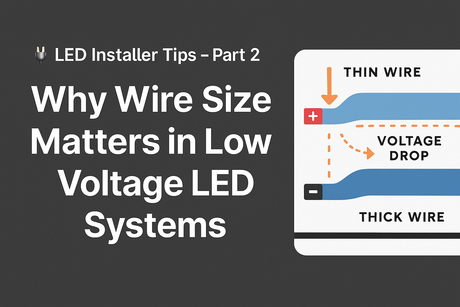

An inadequately matched power source can result in voltage drop—a condition where the brightness diminishes progressively along the length of the strip. This issue is particularly noticeable in longer strips or those with higher power consumption.

Properly selected power supplies address this problem by delivering sufficient voltage and current to maintain uniform brightness across the entire strip. In some cases, specialized solutions like DC low-voltage dimmers or mains supply power sources are used to enhance control and adaptability.

Investing in a high-quality power supply not only improves the lifespan of the LED strips but also maximizes their light output and efficiency.

Which Factors Affect the Quality of LED Strip Lights?

Several factors determine the overall performance and reliability of LED strip lights

Component Quality

The durability and performance of LED strip lights start with the materials used in their construction. High-grade flexible circuit boards and superior electrical components ensure longevity and consistent functionality.

In contrast, using subpar materials, such as cheaper circuit boards, can result in overheating or inconsistent brightness, significantly reducing the lifespan of the product. Investing in quality materials ensures reliable performance over time.

Electrical Components

Efficient power supplies and well-designed electrical current pathways play a vital role in minimizing voltage drop and preventing issues like overheating.

A mismatch in these components can lead to uneven brightness along the strip, affecting overall illumination. Proper power regulation also ensures the strips are safe for prolonged use in both residential and commercial settings.

Manufacturing Process

The precision of the manufacturing process has a direct impact on the reliability of LED strips. Advanced tools, such as pick-and-place machines, ensure accurate placement of the LED chips, while reflow ovens solidify these connections for long-term stability.

Rigorous quality control during production reduces the likelihood of weak connections or defective components, ensuring a higher-quality final product.

Color Temperature and Light Output

Accurate color temperature output is essential for creating the desired atmosphere in various applications. Whether providing warm, white light for a cozy environment or cooler tones for task lighting, consistent color rendering enhances usability.

Similarly, uniform light output ensures even illumination across the strip, making it suitable for both decorative and functional purposes.

Wrap Up

LED strip lights represent a remarkable fusion of advanced technology and thoughtful engineering, making them one of the most versatile lighting solutions available today. These lights utilize a combination of quality components, including flexible circuit boards, SMD LEDs, and precise soldered wiring, all of which work together to deliver consistent light output and adaptability.

With a wide range of options, such as single-strip lights or addressable strips, these products cater to various applications, from enhancing ambiance to providing functional lighting in homes and workplaces.

Understanding the intricate manufacturing process—from placing LED chips on the circuit board with pick-and-place machines to ensuring rigorous testing for voltage drop and color temperature accuracy—helps consumers appreciate the engineering behind these innovative light sources.

When choosing LED strip lights, several factors come into play, including component quality, color temperature output, and reliable electrical components. Opting for products from a reputable company ensures that your strips undergo stringent quality controls, offering better durability and performance over time.

Selecting the right power supply prevents voltage drop issues, maintaining uniform brightness across the entire length of the strip.

Whether you need brighter, higher-output strips for commercial lighting applications or color-changing LED strip lights for creative color temperatures, investing in quality LED strip lights enhances both functionality and aesthetic appeal.

By understanding their features and manufacturing intricacies, you can make an informed decision and enjoy the benefits of this cutting-edge lighting technology in everyday life.

Frequently Asked Questions

What are the different types of LED strip lights available?

There are several types of LED strip lights, including single-color strips, color-changing LED strips, and addressable strips. Single-color strips provide a uniform light output in one color, typically white or warm white.

Color-changing LED strips can cycle through multiple colors, allowing for versatile ambient lighting effects. Addressable strips have individually controlled LEDs, which enable dynamic lighting patterns, ideal for creative and customized displays. Each type caters to different needs, from simple decorative lighting to advanced, programmable applications.

How can I prevent voltage drop in LED strip lights?

Voltage drop occurs when the electrical current loses power as it travels along the length of the LED strip, often resulting in dimmer sections of the strip. To prevent voltage drop, it's crucial to use a power supply that matches the strip’s voltage requirements.

Additionally, choosing high-quality electrical components, such as superior flexible circuit boards and power supplies, can help maintain consistent light output. For longer LED strips, consider using thicker wires or installing a power supply at multiple points along the strip to distribute power evenly.

Can I use LED strips for outdoor installations?

Yes, LED strips can be used for outdoor installations, but it's important to choose LED strips specifically designed for outdoor use. These strips are typically encased in waterproof or weather-resistant coatings to protect the electronics from moisture and environmental elements.

The power supply used for outdoor installations should also be weatherproof and rated for outdoor use. Ensure that the color temperature and light output meet the desired requirements for your outdoor space, whether for accent lighting or functional illumination.