Broken lighting is one of the most frustrating things to deal with. Trust us, we've worked with more non-functioning LED strips than your average home DIY YouTuber.

We hope to make the experience a little less frustrating for you. It's highly likely we have covered your exact issue below. Find the problem you're experiencing, and then follow the steps on how to fix it.

Sometimes things aren't that simple, or you might be dealing with an irreparable LED strip. If you get stuck, please contact us and we'll do all that we can to help.

Safety Tips Before You Begin

When installing or troubleshooting LED strip lights, safety should always come first. Here are some essential safety tips to follow to ensure the job is done safely and effectively:

- Turn off the power: Always ensure the power source is disconnected before starting any installation or repair work on your LED strip lights. This prevents electrical shocks and potential damage to the power supply units.

- Use proper tools: Use insulated tools when working with electrical components to prevent short circuits or injury. Ensure the tape measure, screwdriver, and other tools are in good condition.

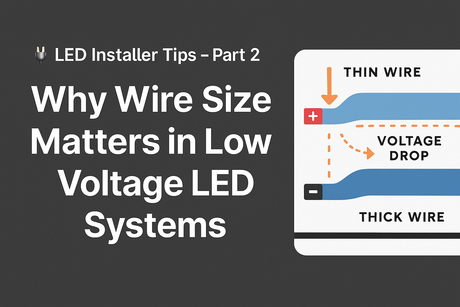

- Check the voltage: Always verify that the voltage on your LED strips and the power supply unit match. Incorrect voltage could lead to overheating or electrical damage.

- Avoid tight bends: Never bend the LED strips at sharp angles as it could damage the diodes or the internal circuit.

- Install in dry, clean areas: To prevent damage to your LED strips and ensure proper adhesion, install them on clean, dry surfaces. This also ensures that the adhesive-backed LED strips remain securely attached.

- Ventilate the area: Proper ventilation helps dissipate heat from the power supply units and strips, reducing the risk of overheating.

8 Common LED Strip Light Problems and How to Fix Them

LED strip lights are a popular choice for mood lighting, but like any electrical component, they can encounter issues. Below, we explore the most common problems that may arise and how you can fix them.

1. Flickering LED Strip Lights

- What Happens: Flickering LED strip lights can be frustrating as they disrupt the light output you expect. The lights may flicker intermittently or constantly, making it difficult to maintain the desired atmosphere.

- Common Causes: Common reasons for flickering include an inadequate power supply, faulty connections, or a voltage drop in the circuit. Sometimes, the LED strip itself may be damaged.

- How to Fix It: First, check the power source and ensure it provides the correct voltage for your LED strip. If the power supply is faulty or inadequate, consider replacing it with a higher-capacity power supply unit. Examine the connections for any loose or faulty wiring. If the flickering persists, you may need to replace the strip or reattach it using double-sided tape.

2. LED Strips Not Sticking Properly

- What Happens: If your LED strips are not adhering properly to the surface, they can peel off over time or fail to stay in place. This results in poor installation, which can lead to further complications such as uneven lighting.

- Common Causes: This problem usually arises due to insufficient adhesive backing, exposure to dust, or improper surface preparation. Some surfaces, like those with moisture or uneven textures, may prevent the adhesive from bonding correctly.

- How to Fix It: Before installation, ensure that the surface is clean, dry, and damage-free. Use a soft cloth and soapy water to remove any dust or oils. For better adhesion, you can use additional adhesive-backed LED strips or reinforce with high-quality double-sided tape. If the adhesive bond weakens over time, consider reapplying fresh adhesive.

3. Uneven Brightness

- What Happens: If your LED strip light displays uneven brightness, some sections may appear dimmer than others, which detracts from the aesthetic value of the lighting installation.

- Common Causes: This is often caused by poor power distribution, an inconsistent voltage supply, or problems with the LED strip's solder pads or wiring. A voltage drop across the strip can also contribute to dimming.

- How to Fix It: Ensure that your LED strip is powered by a stable, constant voltage supply. Check the wiring connections and solder pads for any signs of wear or poor contact. If necessary, replace the strip or repair any faulty sections. For high-density strips or long runs, using a voltage regulator or multiple power supplies can help balance the brightness.

4. Wrong Color Output

- What Happens: If your LED strip lights produce the wrong colors, the expected color temperature may not be achieved, affecting the overall ambiance.

- Common Causes: Incorrect wiring, power supply issues, or poor-quality LED strips can result in color inconsistencies. This can also occur if the voltage is not consistent or if you're using an incompatible power supply unit.

- How to Fix It: Verify that the wiring is correct and that there is no voltage drop along the strip. Replace any faulty power supplies and ensure they are compatible with your LED strip. Additionally, check the manufacturer's specifications to ensure you're using the correct components for your specific LED strip model.

5. Different Colors Along the Strip

- What Happens: When different colors appear along the same LED strip, it's usually noticeable in sections, creating a patchy look that can be distracting.

- Common Causes: This issue often arises from faulty connections or mismatched components. If certain sections of the strip have a bad connection, they may fail to display the correct color or brightness. Another cause could be an inadequate power supply, which could lead to voltage differential across different segments.

- How to Fix It: Inspect the entire strip for faulty connections or damaged wires. Ensure that all connections are secure and correctly soldered. If needed, re-solder any bad connections. To prevent this issue in the future, use a reliable power supply that matches the voltage requirements of your strip.

6. Dead Sections in LED Strip Lights

- What Happens: Dead sections in LED strips, where the lights no longer illuminate, can make your installation look incomplete or defective.

- Common Causes: This is often due to poor soldering, broken wires, or issues with the power supply not delivering enough voltage to certain sections. Sometimes, physical damage to the strip itself, like cracked diodes, can cause sections to die.

- How to Fix It: Start by checking the power source and ensuring it's providing a steady output voltage. Inspect for any broken or loose wires, and repair them as needed. If a section remains dead, replacing the damaged segment or reattaching it with adhesive tape may fix the issue.

7. LEDs Are Flashing

- What Happens: Flashing LEDs can disrupt the lighting effect, especially when it happens sporadically or with no obvious cause.

- Common Causes: Flashing is often caused by loose connections, a faulty power supply, or issues with the LED strip's wiring.

- How to Fix It: Check the entire LED strip for any loose connections or damaged wires. Make sure the power supply is compatible with the voltage requirements of your LED strip. If the issue persists, try replacing the power supply unit or the strip itself.

8. LED Strip Is Hot and Smells Like Burning

- What Happens: If your LED strip gets excessively hot or emits a burning smell, it indicates a serious issue that could lead to permanent damage or even a fire hazard.

- Common Causes: Overheating is commonly caused by inadequate ventilation, excessive current draw, or a defective power supply. Another cause could be the improper installation of the LED strip, leading to poor heat dissipation.

- How to Fix It: Immediately turn off the power and disconnect the strip. Check for proper ventilation around the strip and ensure that it is not coiled up or covered. If overheating continues, consider installing a heat sink or using a different power supply with a better voltage output. Never continue using a strip that emits a burning smell; replace the faulty components.

Tools and Materials for Fixing Removal Issues

Here are the most common tools you might need with your light strip project:

-

Heat Gun

A heat gun helps soften the adhesive on your LED strip, making it easier to remove without damaging the strip or the surface. -

Plastic Scraper

Use a plastic scraper to gently lift the LED strip from the surface once the adhesive is softened. This avoids scratching or damaging the installation area. -

Soft Cloth

A soft cloth is perfect for cleaning the surface after removing the LED strip. It helps remove dust, dirt, and any adhesive residue without causing scratches. -

Soldering Iron

If the LED strip or wiring gets damaged during removal, a soldering iron can be used to reattach broken connections or wires. -

Double-Sided Tape

If the original adhesive no longer sticks properly, double-sided tape is an alternative for reattaching the LED strip securely. -

Adhesive Remover

To clean off stubborn adhesive residue from the surface, an adhesive remover solution or rubbing alcohol can be effective without harming the material. -

Multimeter

A multimeter helps you check the voltage and ensure the power supply is functioning properly, particularly after reattaching or troubleshooting your LED strip. -

Primer or Surface Cleaner

If the removal process has caused any damage to the surface, a primer or surface cleaner can prepare the area for new adhesive or paint. -

Replacement LED Strip

If the LED strip is damaged beyond repair, having a replacement strip on hand ensures you can quickly get your setup back to working condition. -

Mounting Clips (Optional)

For extra security, you can use mounting clips to hold the LED strip in place, especially in areas prone to movement or stress.

How to Troubleshoot a Broken LED Strip Light

When your LED strip stops working or encounters issues, follow these steps to troubleshoot and find a solution.

- Check Power Source: Ensure the power source is functioning properly and delivering the correct voltage for the LED strip.

- Test Voltage: Use a multimeter to test the voltage at different points along the strip. Look for any voltage drops that may indicate faulty wiring or connections.

- Confirm Compatible Parts: Verify that the power supply, connectors, and strip are all compatible with each other in terms of voltage and current.

- Test Accessories: If you're using any additional accessories, such as dimmers or controllers, test them separately to rule out any issues.

- Examine Connections: Check for any loose, damaged, or corroded connections that might cause interruptions in the light output.

Key Takeaways

- Proper maintenance and installation of LED strip lights can help prevent many common issues.

- Voltage drops, faulty power supplies, and poor connections are among the leading causes of malfunction.

- Regular inspection and careful troubleshooting can resolve most problems without needing to replace the entire light strip.

FAQs

What causes my LED strip to flicker?

Flickering in LED strips is often caused by issues with the power supply, loose connections, or voltage drop. The power supply may not provide consistent voltage, which leads to instability in the LED lights. Loose connections, especially at the power source or between strip segments, can also cause interruptions in the current flow.

How can I prevent my LED strip from not sticking?

Before installation, clean the surface thoroughly to remove dust, dirt, or grease that could weaken the adhesive bond. Ensure the surface is dry and free from moisture to maximize adhesion. Using high-quality, adhesive-backed LED strips is key to ensuring a stronger, longer-lasting bond. If the adhesive still fails, consider adding extra support with double-sided tape or another form of mounting solution for better stability.

Why is one section of my LED strip not working?

When one section of your LED strip stops working, it's usually due to faulty connections, broken wires, or poor soldering. The strip's wiring or solder pads may have become damaged, preventing proper electrical flow to that segment. Common issues include loose connections or faulty power supply inputs that don't deliver the required current. To resolve this, inspect the wiring and connections for any visible damage, and ensure that each section is properly connected.