When you need the best glue for metal to metal applications, it’s crucial to pick the right one for your project. Whether for DIY repairs or industrial use, this guide explores the best adhesives for metal, including their benefits and ideal applications. Learn about epoxy, cyanoacrylate, and polyurethane adhesives to find the perfect fit.

Key Takeaways

-

Metal to metal glue is like the superhero of adhesives, creating strong, flexible bonds without the need for heavy machinery—who knew glue could be so buff?

-

Different types of metal adhesives are available, including epoxies, super glues, and polyurethanes, each with their own superpowers—pick your favorite for saving the day!

-

Choosing the right adhesive is key—consider bond strength, curing time, and environmental resistance, because even glue deserves to be picky about its partners!

Understanding Metal to Metal Glue

When it comes to bonding metal, adhesives have become the unsung heroes of the industrial and DIY world. Unlike mechanical fasteners, metal glues create strong chemical bonds that not only hold pieces together but also seal joints at the same time. Imagine having the ability to glue metal pieces with the same strength and integrity as welding but without the heavy equipment and high temperatures. This is where metal bonding adhesive comes into play.

Why choose metal adhesives over traditional mechanical fasteners? For starters, they offer greater flexibility. This is particularly crucial in applications exposed to vibrations and temperature changes, where flexibility can mean the difference between a lasting bond and a quick failure. Plus, metal adhesives act as sealants, providing additional benefits that mechanical fasteners simply can’t offer. Additionally, structural adhesives like epoxy and acrylics are known for their heat and chemical resistance, making them ideal choices for bonding metals in diverse industrial settings.

Cost-effectiveness is another feather in the cap of metal glues. They are often more economical than traditional fasteners, especially when considering the additional tools and labor required for mechanical fastening. Whether for high-stress industrial applications or simple home projects, metal adhesives offer versatility and efficiency.

Types of Metal Adhesives

Best metal glue options come in various flavors, each with its own unique properties and best-use scenarios. From epoxy adhesives known for their versatility to cyanoacrylate adhesives that offer quick bonding solutions, and polyurethane adhesives celebrated for their flexibility, there’s a type of metal glue for every need.

Understanding the strengths and applications of each type of metal adhesive is essential.

Epoxy Adhesives

Ah, the versatile epoxy adhesive! Available in both one-part and two-part systems, epoxy adhesives are the go-to solution for many metal bonding needs. The two-part epoxy systems are particularly renowned for their ability to create strong bonds, making them a favorite for industrial applications. These adhesives are the Swiss Army knife of the bonding world, capable of creating strong bonds with a variety of metals.

Single-component epoxy adhesives often boast the highest tensile strength among metal bonding options. They’re not just strong; they’re also incredibly versatile, suitable for everything from DIY projects to heavy-duty industrial applications.

Whether gluing metal pipes at home or assembling complex machinery, epoxy metal adhesives offer high performance and water-resistant properties.

Cyanoacrylate (Super Glue)

Instant adhesives, such as cyanoacrylate, commonly known as super glue, are the sprinters in the world of adhesives. This metal glue is favored for its quick and instant bonding solutions, making it the go-to for emergency fixes and fast-paced projects. DIY enthusiasts love it for its fast curing time and strong initial bond strength, ideal for quick repairs around the house or in the workshop.

This adhesive is particularly effective for bonding reactive metals like brass and copper, forming a strong bond in mere seconds. Need to fix a broken ornament or a loose car part? Super glue is your best friend. Just remember, with great speed comes great responsibility—ensure surfaces are clean and dry for the best results.

Polyurethane Adhesives

Polyurethane adhesives are the unsung heroes of outdoor projects. Known for their flexibility and durability, these adhesives are particularly ideal for applications exposed to the elements. They cure through moisture, making them perfect for outdoor use where conditions can be less than ideal.

These adhesives are also impact-resistant, providing strong bonds even under fluctuating conditions. Whether you’re gluing metal for garden furniture or assembling a weather-resistant structure, polyurethane adhesives offer the flexibility and strength needed to withstand the test of time and elements.

Best Uses for Metal to Metal Glue

So, where exactly can you put these metal glues to good use? From automotive to construction to DIY projects, metal bonding adhesives are a game-changer. Not only do they offer cost efficiency and reduce assembly steps, but they also speed up processes and allow for flexible bonds.

Retaining compounds, as part of anaerobic adhesive systems, are particularly effective for bonding metals like mild and stainless steel. They are ideal for securing bolts and nuts, and proper surface preparation is crucial for achieving strong adhesion.

Let’s explore the specific applications in more detail.

Automotive Applications

In the automotive industry, structural adhesives are frequently utilized to bond components like roofs and doors to metal frames. The faster curing adhesives significantly reduce downtime, allowing for quicker assembly and turnaround times. This is particularly beneficial in a fast-paced manufacturing environment where every second counts.

UV curable adhesives are increasingly favored for their ability to cure rapidly upon exposure to UV light, enhancing production efficiency. They allow for precise alignment before bonding, ensuring that everything fits perfectly before the glue sets.

Next time you admire the sleek design of a car, remember that metal glues play a vital role in its construction.

Construction and Manufacturing

In the construction sector, metal adhesives are favored for creating strong, reliable joints that resist corrosion. These adhesives help create durable joints for structures like HVAC systems and trailers. They also enhance the aesthetic appeal of structures by providing seamless connections, free of unsightly fasteners.

MS Polymer adhesives are gaining traction in the construction sector due to their flexibility and strong adhesion to a variety of materials, unlike ordinary construction adhesives. From steel beams to metal panels, these adhesives play a crucial role in ensuring the structural integrity and visual appeal of modern constructions.

DIY Projects

For DIY enthusiasts, the types of metal glue suitable for home projects include epoxy, polyurethane, and cyanoacrylate. Common uses for cyanoacrylate, or super glue, in metal bonding include car parts, ornaments, appliances, and models. Need to fix a wobbly table leg or attach a metal handle to a wooden door? These adhesives have got you covered.

One and two-component epoxies are also excellent for bonding magnets and provide strong adhesive properties for various materials. Cyanoacrylate super glue is even a preferred adhesive for bonding pads to musical instruments.

So whether it’s a small repair or a creative project, metal glues are your go-to solution.

Factors to Consider When Choosing Metal to Metal Glue

Choosing the right metal adhesive can be a daunting task given the plethora of options available. Factors such as bond strength, curing time, and environmental resistance play a crucial role in determining the effectiveness of the adhesive.

Let’s delve into these factors to help you make an informed decision.

Bond Strength and Durability

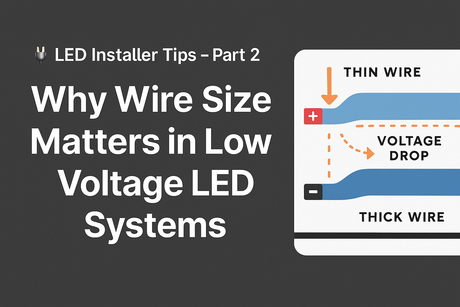

High tensile and shear strength are essential characteristics of effective metal glues for maintaining strong connections over time. Structural adhesives are commonly utilized in manufacturing for their ability to handle load-bearing applications. These adhesives ensure that joints can withstand different types of forces, including tensile and compressive stress.

For DIY enthusiasts, epoxy adhesives are popular for their adaptability and strong bonding capabilities on various metal types. Whether you need a rigid bond or a flexible one, epoxy glues cater to various home repair needs.

So, if you’re looking for a strong bond that lasts, epoxy adhesives are a top choice.

Curing Time and Application

Curing time is a crucial factor that can significantly influence the bonding effectiveness and overall efficiency of the bonding process. Different adhesives require varying curing times, which can significantly influence the bonding effectiveness. For DIY projects, adhesive types such as epoxy and polyurethane are favored for their ease of application and effectiveness.

For those impatient souls who need things done yesterday, fast drying adhesives are a godsend. However, slower setting adhesives can offer stronger bonds over time, making them suitable for more demanding applications. Choose the adhesive based on your project’s specific needs and timelines.

Environmental Resistance

Adhesives should be assessed for their ability to withstand extreme temperatures, moisture, and chemical exposure. Some adhesives can withstand extreme temperatures and are formulated to resist moisture and chemical exposure. Polyurethane adhesives, for instance, are moisture-curing and are particularly well-suited for outdoor applications due to their resistance to UV light.

MS Polymer adhesives are increasingly favored in various industries because they do not require primers and offer high weather resistance. Environmental resistance is a key factor when evaluating metal adhesives, as it determines their suitability for various applications.

So, whether you’re building a metal structure or fixing a garden tool, consider the environmental conditions your adhesive will face.

Surface Preparation for Optimal Bonding

Effective surface preparation is essential for achieving strong adhesive bonds between metals. This involves cleaning the surface to remove contaminants and abrading it to enhance adhesion.

Let’s explore these steps in more detail to ensure you get the best bond possible.

Cleaning the Surface

Removing contaminants like oil, grease, and dust is essential for achieving strong adhesive bonds on metal. Cleaning metal surfaces involves removing contaminants such as oil and dust using solvents like acetone and isopropyl alcohol.

Solvent wipes like acetone or isopropanol, as well as abrasion or grit blasting, are effective methods for removing aluminum oxide prior to bonding. Removing the oxide layer from aluminum is crucial for achieving a strong bond, as it forms a weak interface for adhesives. Additionally, polar solvents can also be utilized in this process.

Before gluing, thoroughly clean your metal surfaces.

Abrading and Priming

Mechanical abrasion is a crucial technique for enhancing the adhesive bonding process between metal surfaces. It helps eliminate heavy surface deposits, allowing for a cleaner bonding surface. Mechanical abrasion enhances the surface profile, promoting better adhesion of metal adhesives.

Overall, the process of mechanical abrasion significantly increases the effectiveness of adhesive bonding. So, grab that sandpaper or grit blaster and get to work—your bond will thank you for it.

Specialized Metal Adhesives

Not all metal adhesives are created equal. Some are designed for specific metals like aluminum, stainless steel, copper, and brass, offering unique properties to ensure optimal bonding. Selecting the appropriate adhesive involves understanding the unique characteristics of most metals to ensure optimal bonding.

Let’s explore the specialized adhesives for these metals to help you make the best choice for your project.

Aluminum Adhesives

When it comes to bonding aluminum, not just any adhesive will do. Polyurethane adhesives are particularly advantageous for outdoor DIY projects due to their water and UV resistance. Effective surface preparation through cleaning and priming is crucial for achieving strong, lasting bonds. Using the appropriate adhesive and following best practices leads to more reliable aluminum bonds.

So, whether you’re assembling aluminum furniture for your garden or fixing an aluminum part in your car, make sure to choose an adhesive designed specifically for aluminum to ensure a bond that stands the test of time.

Stainless Steel Adhesives

Stainless steel, with its mirror finish and resistance to corrosion, requires specialized adhesives for effective bonding. Effective adhesive types for bonding stainless steel include anaerobic systems, cyanoacrylate adhesives, and structural glues. The best surface preparation technique for mirror-finish stainless steel is sandblasting, which helps improve adhesion by creating a rougher surface.

If you’re working on stainless steel, for either industrial applications or kitchen projects, use the appropriate adhesive and surface preparation technique to achieve a bond as strong as steel.

Copper and Brass Adhesives

Copper and brass, known for their excellent conductivity and aesthetic appeal, require adhesives that can handle their unique properties. Anaerobic adhesives cure significantly faster on brass compared to steel due to brass’s high reactivity. These adhesives are essential for creating strong joints in various applications, particularly in plumbing and electrical work.

For optimal bonding with adhesives on copper and brass, clean surfaces thoroughly and remove any oxidation before application. So, next time you’re working with these metals, remember that the right adhesive and proper surface preparation are key to a successful bond.

Innovations in Metal Adhesive Technology

The world of metal adhesives is constantly evolving, with new technologies emerging to improve bond strength and reduce curing times. These innovations allow for more efficient application of metal adhesives in various industries, making them a vital part of modern manufacturing and construction.

UV Curable Systems

UV curable adhesives are designed to bond materials quickly and effectively. One major benefit of UV curable systems is their ability to create invisible bonds, which are perfect for applications where aesthetics matter. UV curable adhesives provide fast curing times, making them very efficient for applications requiring quick assembly.

So, if you need high performance adhesives that offer both speed and aesthetic appeal, UV curable systems are the way to go. Whether you’re working on electronics or automotive components, these adhesives can help streamline your process.

MS Polymer Adhesives

MS Polymer adhesives are gaining popularity for their strong bonding capabilities and flexibility. They are commonly used for bonding metal sheets in vehicles like trains and buses, where durability and flexibility are crucial. Their growing popularity can be attributed to their ability to provide strong, durable bonds under various conditions.

So, if you’re looking for an adhesive that offers both strength and flexibility, MS Polymer adhesives are an excellent choice. Whether it’s for industrial applications or DIY projects, these adhesives can handle a wide range of conditions and materials.

Expert Recommendations for Metal to Metal Glue

Choosing the right metal adhesive is crucial due to the diverse properties and applications of metal adhesives. Different metal adhesives have distinct properties suited for specific applications, making it essential to understand their characteristics. Consulting professionals can help in selecting the proper adhesive or developing a product tailored to specific requirements.

Manufacturers like Permabond provide support through a dedicated team of sales, customer service, and technical professionals. So, whether you’re a seasoned professional or a DIY enthusiast, don’t hesitate to reach out to experts for advice on the best adhesive for your specific needs.

Summary

In conclusion, metal to metal glues offer a versatile and efficient solution for bonding various metals. From the strength and durability of epoxy adhesives to the quick bonding of cyanoacrylate and the flexibility of polyurethane, there’s a metal glue for every application. Remember to consider factors like bond strength, curing time, and environmental resistance when choosing an adhesive, and always prepare the surface properly for the best results. With the right knowledge and tools, you can achieve strong, lasting bonds for all your metal projects.

Frequently Asked Questions

What are structural adhesives primarily used for?

Structural adhesives are like the superglue of the construction world—perfect for holding your favorite paperweights together while ensuring they're as sturdy as your New Year’s resolution! So, if you want to stick things together with a bit more muscle, these bad boys are your best bet.

What types of substrates can 2-part plastic epoxy methacrylate adhesives bond?

Two-part plastic epoxy methacrylate adhesives are like the social butterflies of the bonding world, happily sticking to steel, aluminum, and a whole party of plastics, including acrylics and polycarbonate. So, if you’ve got a weird mix of materials, these adhesives are ready to mingle!

What industries benefit from the use of structural adhesives?

Aerospace, automotive, and construction industries are the glue that holds the world together—quite literally! They all benefit from structural adhesives, proving that sometimes, love really is just a strong bond.

What types of materials can structural adhesives bond?

Structural adhesives are like the ultimate matchmakers, bonding everything from metals to composites to plastics. So, if it’s got a surface, there's a good chance these adhesives can make it their new best friend!

What is the strongest structural adhesive for metal?

If you're looking to stick metal like it’s BFFs at a reunion, epoxy adhesives are the way to go—they're basically the Hulk of adhesives! Just be ready for some serious bonding moments!