We pass on our experience in assisting our clients in projects using LED strip lighting to back light stone walls such as Onyx or Marble.

Our article attempts to help you make the correct choices and at the same time avoid the costly mistake that so many designers and installers make.

- Choosing the correct color (CCT) LED lighting

Backlit onyx and onyx countertops are certainly becoming popular and the Kelvin (color temperature) of the LED lighting certainly plays an essential part in achieving the best result. The color temperature of a light source is the temperature of an ideal black-body radiator that radiates light of comparable color to that of the light source. Color temperature is a characteristic of visible light that has important applications in lighting, photography, videography, publishing, manufacturing, astrophysics, horticulture, and other fields. In practice, color temperature is meaningful only for light sources that do in fact correspond somewhat closely to the radiation of some black body, i.e., those on a line from reddish/orange via yellow and more or less white to blueish white; it does not make sense to speak of the color temperature of, e.g., a green or a purple light. Color temperature is conventionally expressed in kelvins, using the symbol K, a unit of measure for absolute temperature. Color temperatures over 5000 K are called cool colors (bluish white), while lower color temperatures (2700–3000 K) are called warm colors (yellowish white through red). Warm in this context is an analogy to radiated heat flux of traditional incandescent lighting rather than temperature; the spectral peak of warm-colored light is closer to infra-red and most natural warm-colored light sources emit significant infra-red radiation. The fact that warm lighting in this sense actually has a cooler color temperature often leads to confusion

See the following example that we build for a customer to do a presentation to his client

Why this is important in your project is that e.g. you are attempting to light a blue (cool) color stone with a warm color (e.g. 3000k) led your results are not going to be as impressive as using a cooler led e.g. 6000k which has a higher blue light make up

see the following example on our Instagram account that demonstrates kelvin: - https://www.instagram.com/p/BKEShibDk-Z/?taken-by=wired4signs.usa

If you are unsure about the exact color white light to use there are LED options such as the following link that enable one to change the CCT by means of remote control and CCT adjustable LED strip: click on the following pictures to get further information.

- Choosing high CRI LED lights

The CRI of a light source does not indicate the apparent color of the light source; that information is under the rubric of the correlated color temperature (CCT). The CRI is determined by the light source's spectrum. A color rendering index (CRI) is a quantitative measure of the ability of a light source to reveal the colors of various objects faithfully in comparison with an ideal or natural light source.

Using high quality, high CRI leds is going bring out the true colors and therefore best visual results in your project

Some examples of such LEDS are below

https://www.wired4signsusa.com/collections/high-cri-flex-strip

- Choosing the correct LED product

The most popular LED solutions for backlighting are LED strip lighting, LED rigid bars. See examples in links below.

Because of various densities of the stone substates you will need to insist on running trials to ensure the correct spacing of the leds to avoid hot spots or visible light lines

https://www.wired4signsusa.com/pages/led-flexible-strip-lighting

- Mounting of the LEDs

A frequently listed advantage of LEDs is that they do not produce heat. In a way, this is true, LEDs are cool to the touch because they usually do not produce heat in the form of infrared (IR) radiation. This obviously doesn’t go for IR specific LEDs.IR radiation is what actually heats incandescent bulbs and other light sources, making them hot to the touch. Without IR radiation, LEDs are able to be placed in spots where the heat from other sources would cause a problem (grow lights, reef tank lights, illuminating food, etc.). Although LEDs are cool to the touch, within the devices themselves, there is plenty of unwanted heat. This heat comes from the inefficiency of the semiconductors that generate the light. The radiant efficiency (total optical output power divided by total electrical input power) of LEDs is typically between 5 and 40%, meaning that 60-95% of the input power is lost as heat. So, what do you do with all this excess internal heat?!Why should LED junction temperature be managed? With high-power LEDs, it is crucial that you remove heat through efficient thermal management. Without good heat sinking, the junction (internal) temperature of the LED rises, causing the LED characteristics to change for the bad.

As the junction temperature of an LED increases, both the forward voltage and the lumen output decreases. Not only is this decreasing the brightness and efficiency of your LED but this junction temperature affects the overall lifetime of the LED as well. LEDs don’t usually fail catastrophically (although some may, especially if you over heat them); instead, the lumen output of the LED will decrease over time. Higher junction temperatures lead to faster LED deterioration. Therefore, it is crucial to keep your LED junction temperature low. Also, take note that if you are over driving your LED (putting more current to it than what it is rated) this will drive temperatures up so high that permanent damage can occur.

Heat sinks are an important part of LED lighting because they provide the path for heat to travel from the LED light source to outside elements. Heat sinks can dissipate power in three ways: conduction (heat transfer from a solid to a solid), convection (heat transfer from a solid to a moving fluid, air in most cases), or radiation (heat transfer from two bodies at different temperatures through thermal radiation).

Therefore, your backing panel or where ever your mount LEDs need to be able to disperse the generated heat. We have recommended the use of aluminum sheets on installations with the allowance of plenty air circulation and in some situations even using the aid of extraction fans and thermostats

See the image below where our client used aluminum sheeting to dissipate the generated heat with plenty allowance for air circulation

- Choosing and placing the power supplies

There are many low voltage power supplies on the market but it is important to bear the following in mind when installing your PSU

To ensure maximum life of your LED PSU (Power supply unit) we provide some useful tips -

The environment the PSU is installed in, does not exceed the maximum ambient temperature specified by the manufacturer, e.g. If the unit is installed inside a weather-proof box, ensure the ambient temperature inside the box does not exceed the maximum ambient temperature spec of the relevant PSU.Eg. HLG240-12A Ta = 50°C

Ensure ample ventilation around the unit always

Install PSU horizontally and not vertically as this has a detrimental effect on the dispersion of heat through the unit

The operating temperature of the unit must never exceed its maximum operating temperature specified by the manufacturer.eg. HLG240-12A Tc = 90°C

The material that the PSU is mounted on must be capable of dispersing heat, e.g. Aluminum disperses of heat whereas wood is an insulator and can lead to heat build up

The PSU must be secured in the correct manner, i.e. Fixed down with screws/bolts and not hanging by the wires

Allow adequate spacing between PSU’s is at a minimum distance of 4 inches

All connections should be sealed to prevent corrosion

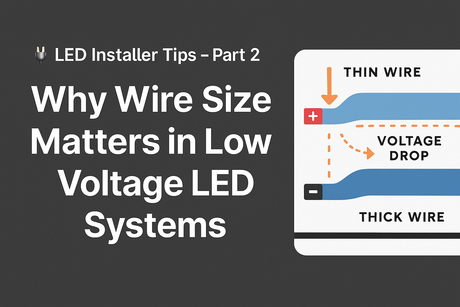

Use the correct gauge wire to handle the current to and from the PSU

We recommend that a safe load margin of 70 – 80% is applied when installations are in areas of warmer climate

Consult the product spec sheet for load at ambient temperature graph

Make sure that the connectors are sufficiently spec’d for the load current

Use connectors that make excellent connection with the wire used, i.e. Compressed plate connectors, splicers, etc. – Not standard screw terminal blocks

When your installation is on a large building, ensure that lightening/surge protection, reliable grounding and solid state circuit-breakers are present and fully functional

Ensure that your mains power is stable and clean. E.g. A building with several lifts or heavy machinery can influence the quality of power. If the installation is poor, large voltage drops can be experienced and effect the life of the PSU

We recommend that the transformers are mounted in an easily accessible area

Our years of experience have taught us to only sell brands that have been tried and tested in the harshest environments.

See our indoor LED PSUs and outdoor LED PSU’s range here

Indoor range: - https://www.wired4signsusa.com/collections/non-waterproof-meanwell-driver

Outdoor range: - https://www.wired4signsusa.com/collections/waterproof-meanwell-drivers

See in the image below how we designed steel crates to protect the PSUs and cooled be means of extractors

It is critical that the PSUs are kept cool and if at all possible mounted in an air conditioned environment

And what a beautiful final result .....